maxon motor control

EPOS Positioning Controller

EPOS Application Note: Interpolation Position Mode

18

maxon motor control

Edition December 2008 / Subject to change

3.7

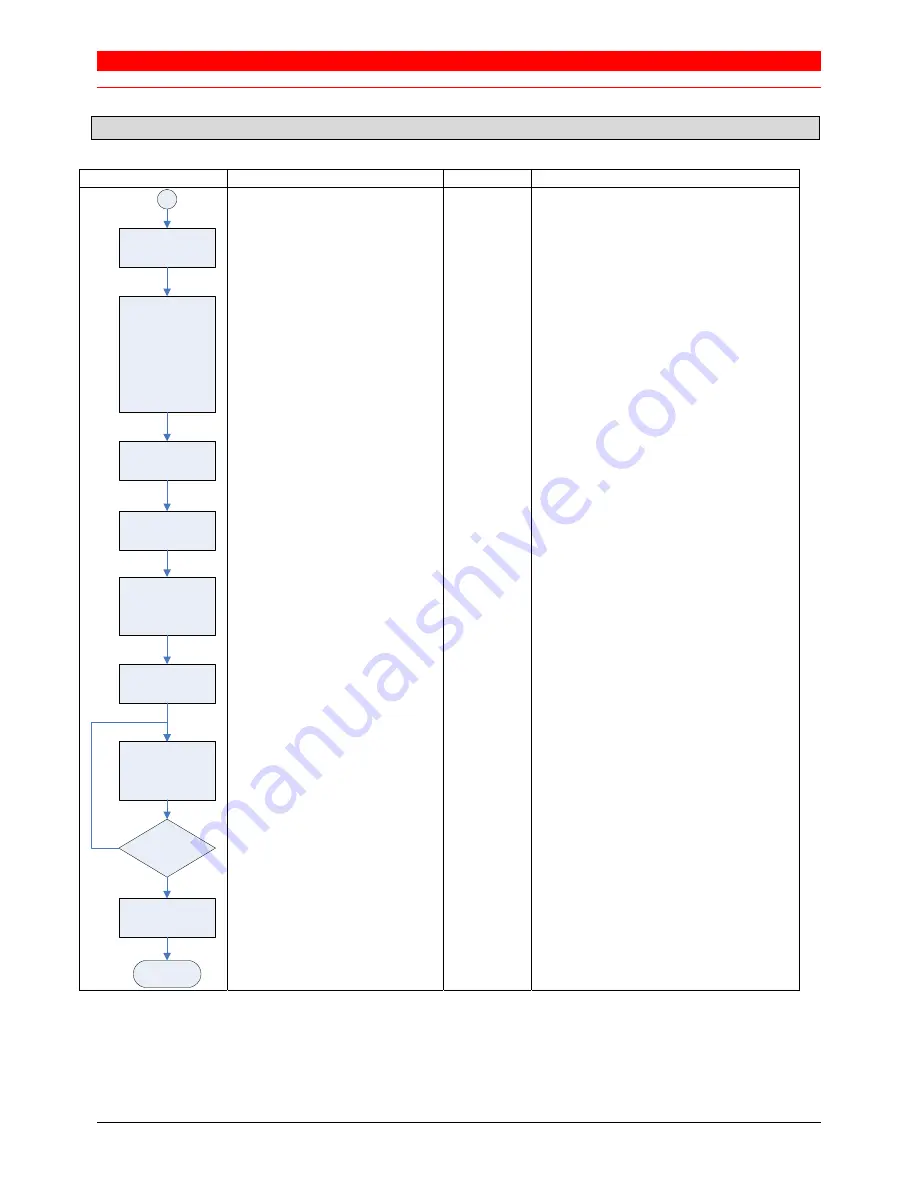

Typical IPM commanding sequence

Diagram

Object name

Object

User value [default value]

Modes of Operation

0x6060-00

0x07 (Interpolated Position Mode)

Max. Following Error

Min. Position Limit

Max. Position Limit

Max. Profile Velocity

Max. Acceleration

Profile Velocity

Profile Acceleration

Quick Stop Deceleration

0x6065-00

0x607D-01

0x607D-02

0x607F-00

0x60C5-00

0x6081-00

0x6083-00

0x6084-00

Application specific [2000 qc]

Application specific [-2147483648 qc]

Application specific [2147483647 qc]

Motor specific [25000 rpm]

Application specific [4294967295 rpm/s]

Application specific [1000 rpm]

Application specific [10000 rpm/s]

Application specific [10000 rpm/s]

Controlword (Shutdown)

Controlword (SwitchOn)

0x6040-00

0x6040-00

0x0006

0x000F

Buffer clear

0x60C4-06

0x01

Interpolation data record

0x20C1-00

Reference points (PVT)

(minimum 2 points!)

Controlword (enable ip mode)

0x6040-00

0x001F

if (Interpolation buffer status)

do

Interpolation data record

until (Interpolation buffer status)

0x20C4-01

0x20C1-00

0x20C4-01

Bit 0 == 1 (Underflow Warning)

Reference point (PVT)

Bit 1 == 1 (Overflow Warning)

Interpolation data record

0x20C1-00

Reference point (PVT) with time = 0

Set Operation

Mode

Set Parameters

Enable Device

Enable Buffer

access

Feed Reference

Points

Activate

Interpolation

Feed Reference

Points

End

More Points?

Feed Profile End

Yes

Table 17:

Typical Commanding sequence

During the interpolation is active the feeding of new reference points is the main task. To minimize the

communication overhead it makes sense to map the “Interpolation data record” in a (asynchronous) receive PDO. If

the “Interpolation buffer status” is mapped to an event trigger transmit PDO (maybe together with the Statusword)

the processing of the reference point feeding could be implemented simpler.