31

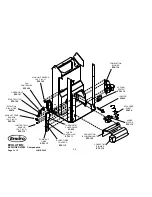

PARTS LIST

EF-037

POWER UP TIMER

20-038

EF5 CAST TOP

EF-043 START-UP

SWITCH

20-045

EF 5 FIREBOX BRICK LINER

EF5-101

S.S. SIDE PANELS (2) AND

HOPPER LID

20-054

EF5 S.S. BURN POT LINER

EF5-103 EVOLUTION

HEARTH PAD

20-073

EF 5 UPGRADE KIT

EF5-104

OUTSIDE COMBUSTION BLOWER

HOUSING

20-074

EF 5 DIAL-A-FIRE

EF5-105

200 HIGH LIMIT TEMP SENSOR MR

20-094

EF5 TOP GLASS RETAINER

EF5-106

FAN CONTROLLER

50-084

EF5 THERMOSTAT INTERFACE

ONLY

EF5-107 GREEN

LIGHT

50-088 EF5 DOOR GASKET (60 INCHES)

EF5-109

120

°

F EXHAUST TEMP SENSOR

50-096

EF5 EXTERIOR EXHAUST ADAPTER

EF5-110

120

°

F IGNITION TEMP SENSOR

50-097

EF5 NICKEL LOUVER SET

EF5-112

AUGER TIMER CONTROL

50-162

EF5 ASH LIP LOUVER NICKEL

EF5-113 POWER

UP

TIMER

EF5-114 COMBUSTION

BLOWER

EF5-115 VACUUM

SWITCH

EF5-116 AUGER

MOTOR

EF5-118 AUGER

EF5-119 CONVECTION BLOWER

EF5-120 CONVECTION

BLOWER MOUNT

EF5-121

CONTROL PANEL DOOR

EF5-122 CONTROL

PANEL

EF5-123

CONTROL PANEL DECAL

EF5-124

EF5 FIREBOX LINER

EF5-128 BURN

POT

EF5-129 ASH

PAN

EF5-131

ASH PAN COVER

EF5-134 DOOR

HANDLE

EF5-136

PAINTED DOOR ONLY

EF5-137

SLIDER DAMPER PLATE

EF5-138 HEAT

EXCHANGER

ROD

EF5-139 BACK

GRILL

EF5-140

HOPPER LID PAINTED

EF5-149 IEC

POWER

CORD

20-018

EF5 LEVELING LEGS

20-019

EF5 OWNERS MANUAL

20-020

EF5 HARDENED BUSHING

20-021

EF5 WIRING HARNESS

20-022

EF5 IGNITER 120 V

20-023

EF5 GLASS (356 X 356 MM )

20-024 EF5

AUGER

SHAFT

20-025

EF5 LIGHTING INSTRUCTIONS

20-026

EF5 THERMOSTAT CONTROLLER

20-029

EF5 S.S. CAB SIDE LEFT

20-030

EF5 S.S. CAB SIDE RIGHT

20-031

EF5 PAINTED CAB SIDE LEFT

20-032

EF5 PAINTED CAB SIDE RIGHT

Summary of Contents for EF-V EVOLUTION

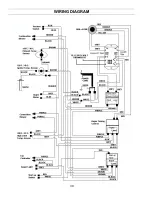

Page 30: ...30 WIRING DIAGRAM...