Such adjustment should be made without extracting the filler head, to prevent the liquid from

spilling out of the bag.

Using the handwheel as indicate before raise the prong until the liquid inside the tube ebbs back into

the bag. Block the prong in place at this new height and remove the filling head. The level of the

liquid inside the bag must remain within the rigid ring section. The height thus determined will be

valid for all the bags of the same capacity. When the size of the bag varies the height will need to be

readjusted.

4.4 DIFFERENT BAG FORMAT

. To modify the bag format utilised perform the following

corrections:

Check the height of the prong and if necessary adjust in relation to the size of the bag

Set the no. of litres needed to fill the new bag format

Adjust, if necessary, only the COR parameter

Before starting up the machine for the first filling operation press the RESET button for 5

seconds and check that the counter “QUANTITA’ EROGATA” is at 0. If a different value is

shown keep the RESET button pressed until the O figure appears.

All repairs must be carried out directly by Enoitalia srl or by qualified and specialised staff

In the case of any repair operations use original spare parts only by contacting the retailer or

manufacturer directly.

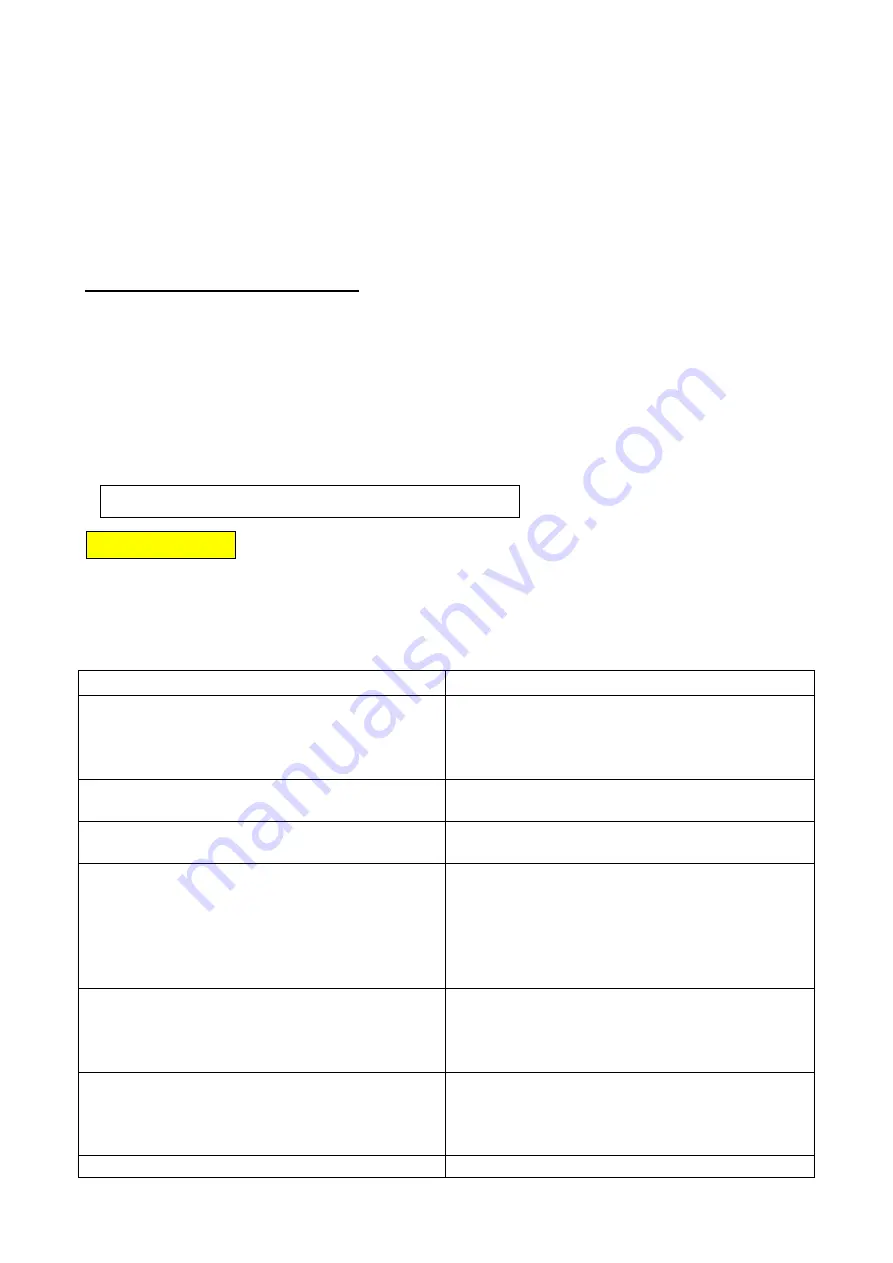

PROBLEM

REMEDY

The filling machine does not stop upon reaching

the no. of litres set.

Check that the compressor is turned on and that

the air tubes are open.

Check that the air tube is connected to the

pneumatic valve.

The filling machine stops after a few litres without

reaching the set level.

Press the reset button and check that all the

counters show the correct start value.

It is difficult to insert the filler head inside the

bags.

Check that the head is centred and adjust using the

screws for the purpose.

The pincer cannot get the cap out.

Check the exact position of the cap and if

necessary adjust it using the handwheel for the

purpose.

Check the load springs of the pincer.

Check that the cap is compatible with the pincer

used and if necessary contact the manufacturer.

The air depression tube fills with liquid.

Raise the fork holding the bags.

If only a matter of a few drops this is not a

problem since they will be expelled from the

tubes at the next filling operation.

Liquid leaks onto the lower shelf.

These are drops of liquid which are expelled from

the air depression outlet. These drops will not

cause any damage to the system, but to collect

them put a recipient under the outlet tube.

Liquid leaks out of the decanting pump.

Check and replace the mechanical pump seal.

WARNING

5. POSSIBLE CAUSES OF MALFUNCTIONING

PULIZIA, MANUTENZIONE RIMESSAGGIO

Summary of Contents for BB 20

Page 17: ......