244

WSG-1068 STARTER SYSTEM

Component Tests

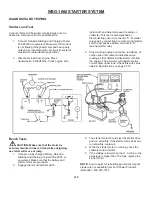

Starter Motor - Voltage Drop Test

WARNING: WHEN REPAIRING THE STARTER

MOTOR OR PERFORMING OTHER UNDERHOOD

WORK IN THE VICINITY OF THE STARTER MOTOR,

BE AWARE THAT THE HEAVY GAUGE BATTERY

INPUT LEAD AT THE STARTER SOLENOID IS

“ELECTRICALLY HOT” AT ALL TIMES. WHEN

SHORTED TO GROUND, MAY CAUSE PERSONAL

INJURY.

CAUTION: A protective cap or boot is provided over

the battery input terminal on all vehicle lines and

must be replaced after repairing. Failure to replace

protective cap could cause electrical short that may

damage electrical system. Be sure to disconnect

the battery ground cable before repiaring the starter

motor.

NOTE:

Always connect the 73 Digital Multimeter at the

component terminal rather than at the wiring end

connector. Making a connection at the wiring end

connector could result in false readings because the

meter will not pick up a high resistance between the

wiring connector and the component.

Starter Motor - Motor Feed Circuit

1. Make sure the battery is fully charged.

2. Connect a remote starter switch between the

starter motor solenoid S-terminal and the battery

positive (+) terminal.

3. Connect the 73 Digital Multimeter positive lead

to the battery positive (+) post. Connect negative

lead to the starter motor solenoid M-terminal.

4. E

n

gage the remote starter switch. Read and record

the voltage. The voltage reading should be 0.5

volts or less.

5. If the voltage reading is 0.5 volts or less -- Refer

to“Starter Motor - Motor Ground Circuit” on page

14.

6. If the voltage reading is greater than 0.5 volts,

indicating excessive resistance, move the 73

Digital Multimeter negative lead to the starter

motor B-terminal and repeat the test. If the

voltage reading at the B-terminal is lower than

0.5 volts, the concern is either in the

connections at the starter motor solenoid or in

the starter motor solenoid contacts.

7. Remove the cables from the starter motor

solenoid B-, S- and M-terminals. Clean the

cables and connections and reinstall the cables

to the proper terminals. Repeat Steps 3 through

6. If the voltage drop reading is still greater than

0.5 volts when checked at the M-terminal or less

than 0.5 volts when checked at the B-terminal,

the concern is in the solenoid contacts. Replace

the starter motor.

8. If the voltage reading taken at the starter motor

solenoid B-terminal is still greater than 0.5 volts

after cleaning the cables and connections at the

solenoid, the concern is either in the positive (+)

battery cable connection or in the positive

battery cable itself.

9. By moving the 73 Digital Multimeter negative

lead toward the battery and checking each

mechanical connection point, the excessive

voltage drop can be located. When the high

reading disappears, the last mechanical point

that was checked is the concern. Repair or

replace this connection as required.

Summary of Contents for WSG-1068

Page 1: ...WSG 1068 6 8 LITER INDUSTRIAL ENGINE SERVICE MANUAL EDI 1050180 March 2009 ...

Page 12: ...6 WSG 1068 GENERAL INFORMATION DIAGNOSIS AND TESTING Special Tools ...

Page 14: ...8 WSG 1068 GENERAL INFORMATION Symptom Chart Condition Possible Source Action ...

Page 15: ...9 WSG 1068 GENERAL INFORMATION ...

Page 48: ...32 WSG 1068 ENGINE Module View ...

Page 49: ...33 WSG 1068 ENGINE Engine Intake Components ...

Page 50: ...34 WSG 1068 ENGINE ...

Page 51: ...35 WSG 1068 ENGINE Low End Components ...

Page 52: ...36 WSG 1068 ENGINE ...

Page 53: ...37 WSG 1068 ENGINE Upper End Components ...

Page 54: ...38 WSG 1068 ENGINE ...

Page 55: ...39 WSG 1068 ENGINE Major Front End Components ...

Page 56: ...40 WSG 1068 ENGINE DIAGNOSIS AND TESTING Refer to Section 01 for basic mechanical concerns ...

Page 65: ...49 WSG 1068 ENGINE 4 Tighten the nuts and bolts in the sequence shown ...

Page 68: ...52 WSG 1068 ENGINE 4 Tighten the bolts in the sequence shown 5 Reinstall the PCV valve ...

Page 75: ...59 WSG 1068 ENGINE ...

Page 87: ...71 WSG 1068 ENGINE Camshaft Assembly Timing Mark Alignment ...

Page 88: ...72 WSG 1068 ENGINE Timing Chains Camshaft Gears and Crankshaft Gears Alignment ...

Page 137: ...121 WSG 1068 ENGINE 1 Remove the Camshaft Holding Tool from the camshaft 6250 ...

Page 143: ...127 WSG 1068 ENGINE 10 Install the roller followers 11 Remove the Valve Spring Spacer ...

Page 155: ...139 WSG 1068 ENGINE 35 Install the timing chain guides 6K297 ...

Page 172: ...156 WSG 1068 ENGINE SPECIFICATIONS ...

Page 173: ...157 WSG 1068 ENGINE ...

Page 174: ...158 WSG 1068 ENGINE ...

Page 180: ...164 WSG 1068 IGNITION SYSTEM ...

Page 188: ...172 WSG 1068 IGNITION SYSTEM Firing Order ...

Page 190: ...174 WSG 1068 IGNITION SYSTEM Harness Connector Pinout Description I O Input Output ...

Page 194: ...178 WSG 1068 IGNITION SYSTEM Engine Controls ...

Page 195: ...179 WSG 1068 IGNITION SYSTEM Engine Sensors part of SK2U1L 12A200 BA ...

Page 197: ...181 WSG 1068 IGNITION SYSTEM 90 Pin GCP Connector ...

Page 199: ...183 WSG 1068 IGNITION SYSTEM ...

Page 204: ...188 WSG 1068 FUEL SYSTEM ...

Page 225: ...209 WSG 1068 COOLING SYSTEM CHT Sensor Data Temperature Sensor Characteristics ...

Page 229: ...213 WSG 1068 COOLING SYSTEM PINPOINT TEST A LOSS OF COOLANT ...

Page 230: ...214 WSG 1068 COOLING SYSTEM PINPOINT TEST A LOSS OF COOLANT Continued ...

Page 232: ...216 WSG 1068 COOLING SYSTEM PINPOINT TEST B THE ENGINE OVERHEATS Continued ...

Page 233: ...217 WSG 1068 COOLING SYSTEM ...

Page 234: ...218 PINPOINT TEST B THE ENGINE OVERHEATS Continued WSG 1068 COOLING SYSTEM ...

Page 239: ...223 WSG 1068 CHARGING SYSTEM DIAGNOSIS AND TESTING Recommended Accessory Wiring ...

Page 243: ...227 WSG 1068 CHARGING SYSTEM Symptom Chart ...

Page 245: ...229 WSG 1068 CHARGING SYSTEM ...

Page 259: ...243 WSG 1068 STARTER SYSTEM ...

Page 278: ...262 WSG 1068 ENGINE CONTROLS Diagrams and Schematics Symbols ...

Page 279: ...263 WSG 1068 ENGINE CONTROLS GCP Power Distribution Box ...

Page 281: ...265 WSG 1068 ENGINE CONTROLS Power Distribution ...

Page 282: ...266 WSG 1068 ENGINE CONTROLS Ignition System ...

Page 283: ...267 WSG 1068 ENGINE CONTROLS Starting System ...

Page 284: ...268 WSG 1068 ENGINE CONTROLS Charging System ...

Page 285: ...269 WSG 1068 ENGINE CONTROLS Engine Controls Sensors 1 of 2 ...

Page 286: ...270 WSG 1068 ENGINE CONTROLS Engine Controls Sensors 2 of 2 ...

Page 287: ...271 WSG 1068 ENGINE CONTROLS Fuel Injectors ...

Page 289: ...273 Engine Controls Dry Fuel EPR ...

Page 290: ...274 WSG 1068 ENGINE CONTROLS Engine Component Locator View ...

Page 305: ...289 WSG 1068 ENGINE CONTROLS Engine Performance While Under Load ...

Page 306: ...290 WSG 1068 ENGINE CONTROLS Engine Concerns ...

Page 315: ...299 WSG 1068 ENGINE CONTROLS SPECIFICATIONS ...

Page 320: ...304 WSG 1068 METRICS ENGLISH METRIC CONVERSION ...

Page 321: ...305 WSG 1068 METRICS DECIMAL AND METRIC EQUIVALENTS TORQUE CONVERSION ...

Page 323: ...307 WSG 1068 METRICS ...

Page 324: ...308 WSG 1068 METRICS ...

Page 325: ...309 WSG 1068 METRICS ...

Page 326: ...310 WSG 1068 METRICS ...

Page 327: ...311 WSG 1068 METRICS ...

Page 328: ...312 WSG 1068 METRICS ...

Page 329: ...313 WSG 1068 METRICS ...

Page 330: ...314 ...