167

WSG-1068 IGNITION SYSTEM

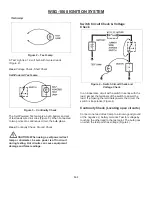

The Fuel Select Switch

In the event that the engine is operated on alternate

fuels such as natural gas, compressed natural gas

(CNG), or liquefied petroleum gas (LPG), timing can be

modified with a Fuel Select Switch.

NOTE

: Fuel select switch is supplied by the customer.

Sends a signal to the GCP to adjust base timing

for alternate fuel

Is manually controlled.

With this system, the GCP monitors the engine load,

speed, operating temperature, air intake temperature

and decides what degree of spark advance is correct for

all of the operating conditions. Because timing is set for

life inherently in the design of the engine, and there are

no moving parts in the ignition system itself, no

maintenance is required except for periodic spark plug

checks. The system provides for fixed spark advance at

start-up, for cold weather starting, and for “average

value” default settings in case of component failure.

Particular attention has been given to spark optimization

for excellent fuel economy and power in the warm-up

mode.

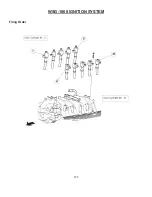

The spark plugs are paired so that one plug fires during

the compression stroke and its companion plug fires

during the exhaust stroke. The next time that coil is fired,

the plug that was on exhaust will be on compression,

and the one that was on compression will be on exhaust.

The spark in the exhaust cylinder is wasted but little of

the coil energy is lost.

Run Mode

The GCP interprets engine speed above100 RPM as

Run Mode.

The Base Spark Advance (BSA) is calculated by the

(GCP) module processing the engine speed and load

plus sensors mentioned in operation of this section and

Fuel Select Switch.

Inputs to the GCP Effecting the Ignition

The spark strategy is based on sensors and manifold

vacuum input to the GCP module, which include the

following inputs:

Crankshaft Position Sensor (CKP Sensor)

The CKP sensor is a magnetic transducer mounted on

the engine block adjacent to a pulse wheel located on

the crankshaft. By monitoring the crankshaft mounted

pulse wheel

A

, the CKP is the primary sensor for

ignition information to the GCP. The pulse wheel located

behind the crankshaft pulley

B

, has a total of 39 teeth

spaced 9 degrees apart with one empty space

C

for a

missing tooth. An A/C voltage signal is generated which

increases with engine rpm and provides engine speed

and crankshaft position information to the GCP. By

monitoring the pulse wheel, the CKP sensor signal

indicates crankshaft position and speed information to

the GCP. The CKP sensor is also able to identify piston

travel in order to synchronize the ignition system and

provide a way of tracking the angular position of the

crankshaft relative to a fixed reference for the CKP

sensor configuration. GCP also uses the CKP signal to

determine if a misfire has occurred by measuring rapid

decelerations between teeth.

Summary of Contents for WSG-1068

Page 1: ...WSG 1068 6 8 LITER INDUSTRIAL ENGINE SERVICE MANUAL EDI 1050180 March 2009 ...

Page 12: ...6 WSG 1068 GENERAL INFORMATION DIAGNOSIS AND TESTING Special Tools ...

Page 14: ...8 WSG 1068 GENERAL INFORMATION Symptom Chart Condition Possible Source Action ...

Page 15: ...9 WSG 1068 GENERAL INFORMATION ...

Page 48: ...32 WSG 1068 ENGINE Module View ...

Page 49: ...33 WSG 1068 ENGINE Engine Intake Components ...

Page 50: ...34 WSG 1068 ENGINE ...

Page 51: ...35 WSG 1068 ENGINE Low End Components ...

Page 52: ...36 WSG 1068 ENGINE ...

Page 53: ...37 WSG 1068 ENGINE Upper End Components ...

Page 54: ...38 WSG 1068 ENGINE ...

Page 55: ...39 WSG 1068 ENGINE Major Front End Components ...

Page 56: ...40 WSG 1068 ENGINE DIAGNOSIS AND TESTING Refer to Section 01 for basic mechanical concerns ...

Page 65: ...49 WSG 1068 ENGINE 4 Tighten the nuts and bolts in the sequence shown ...

Page 68: ...52 WSG 1068 ENGINE 4 Tighten the bolts in the sequence shown 5 Reinstall the PCV valve ...

Page 75: ...59 WSG 1068 ENGINE ...

Page 87: ...71 WSG 1068 ENGINE Camshaft Assembly Timing Mark Alignment ...

Page 88: ...72 WSG 1068 ENGINE Timing Chains Camshaft Gears and Crankshaft Gears Alignment ...

Page 137: ...121 WSG 1068 ENGINE 1 Remove the Camshaft Holding Tool from the camshaft 6250 ...

Page 143: ...127 WSG 1068 ENGINE 10 Install the roller followers 11 Remove the Valve Spring Spacer ...

Page 155: ...139 WSG 1068 ENGINE 35 Install the timing chain guides 6K297 ...

Page 172: ...156 WSG 1068 ENGINE SPECIFICATIONS ...

Page 173: ...157 WSG 1068 ENGINE ...

Page 174: ...158 WSG 1068 ENGINE ...

Page 180: ...164 WSG 1068 IGNITION SYSTEM ...

Page 188: ...172 WSG 1068 IGNITION SYSTEM Firing Order ...

Page 190: ...174 WSG 1068 IGNITION SYSTEM Harness Connector Pinout Description I O Input Output ...

Page 194: ...178 WSG 1068 IGNITION SYSTEM Engine Controls ...

Page 195: ...179 WSG 1068 IGNITION SYSTEM Engine Sensors part of SK2U1L 12A200 BA ...

Page 197: ...181 WSG 1068 IGNITION SYSTEM 90 Pin GCP Connector ...

Page 199: ...183 WSG 1068 IGNITION SYSTEM ...

Page 204: ...188 WSG 1068 FUEL SYSTEM ...

Page 225: ...209 WSG 1068 COOLING SYSTEM CHT Sensor Data Temperature Sensor Characteristics ...

Page 229: ...213 WSG 1068 COOLING SYSTEM PINPOINT TEST A LOSS OF COOLANT ...

Page 230: ...214 WSG 1068 COOLING SYSTEM PINPOINT TEST A LOSS OF COOLANT Continued ...

Page 232: ...216 WSG 1068 COOLING SYSTEM PINPOINT TEST B THE ENGINE OVERHEATS Continued ...

Page 233: ...217 WSG 1068 COOLING SYSTEM ...

Page 234: ...218 PINPOINT TEST B THE ENGINE OVERHEATS Continued WSG 1068 COOLING SYSTEM ...

Page 239: ...223 WSG 1068 CHARGING SYSTEM DIAGNOSIS AND TESTING Recommended Accessory Wiring ...

Page 243: ...227 WSG 1068 CHARGING SYSTEM Symptom Chart ...

Page 245: ...229 WSG 1068 CHARGING SYSTEM ...

Page 259: ...243 WSG 1068 STARTER SYSTEM ...

Page 278: ...262 WSG 1068 ENGINE CONTROLS Diagrams and Schematics Symbols ...

Page 279: ...263 WSG 1068 ENGINE CONTROLS GCP Power Distribution Box ...

Page 281: ...265 WSG 1068 ENGINE CONTROLS Power Distribution ...

Page 282: ...266 WSG 1068 ENGINE CONTROLS Ignition System ...

Page 283: ...267 WSG 1068 ENGINE CONTROLS Starting System ...

Page 284: ...268 WSG 1068 ENGINE CONTROLS Charging System ...

Page 285: ...269 WSG 1068 ENGINE CONTROLS Engine Controls Sensors 1 of 2 ...

Page 286: ...270 WSG 1068 ENGINE CONTROLS Engine Controls Sensors 2 of 2 ...

Page 287: ...271 WSG 1068 ENGINE CONTROLS Fuel Injectors ...

Page 289: ...273 Engine Controls Dry Fuel EPR ...

Page 290: ...274 WSG 1068 ENGINE CONTROLS Engine Component Locator View ...

Page 305: ...289 WSG 1068 ENGINE CONTROLS Engine Performance While Under Load ...

Page 306: ...290 WSG 1068 ENGINE CONTROLS Engine Concerns ...

Page 315: ...299 WSG 1068 ENGINE CONTROLS SPECIFICATIONS ...

Page 320: ...304 WSG 1068 METRICS ENGLISH METRIC CONVERSION ...

Page 321: ...305 WSG 1068 METRICS DECIMAL AND METRIC EQUIVALENTS TORQUE CONVERSION ...

Page 323: ...307 WSG 1068 METRICS ...

Page 324: ...308 WSG 1068 METRICS ...

Page 325: ...309 WSG 1068 METRICS ...

Page 326: ...310 WSG 1068 METRICS ...

Page 327: ...311 WSG 1068 METRICS ...

Page 328: ...312 WSG 1068 METRICS ...

Page 329: ...313 WSG 1068 METRICS ...

Page 330: ...314 ...