Enertech Global, LLC

22

WS Rev. E Models

Installation and Operations Manual

Features

Enertech Global geothermal heat pump controls leverage a

modular approach for controlling heat pump operation. The

control system uses a combination of printed circuit boards,

depending upon the features equipped in a particular unit.

This approach simplifies installation and troubleshooting, and

eliminates features that are not applicable for some units.

Microprocessor Features and Operations

Enertech Global geothermal heat pump controls provide a

unique modular approach for controlling heat pump

operation. The control system uses one, two, or three printed

circuit boards, depending upon the features of a particular

unit. This approach simplifies installation and troubleshooting,

and eliminates features that are not applicable for some

units.

A microprocessor-based printed circuit board controls the

inputs to the unit as well as outputs for status mode, faults,

and diagnostics. A status LED and LED(s) for each fault are

provided for diagnostics.

A removable low voltage terminal strip provides the

necessary terminals for thermostat connections. Some

models offer an additional removable terminal strip for

accessory wiring connections.

Startup/Random Start

The unit will not operate until all the inputs and safety

controls are checked for normal conditions. A ten to twenty

second random start delay is added at power up and

whenever a Y1 call is received. This avoids multiple units from

being energized at the same time after power loss or other

situations.

Short Cycle Protection (ASC)

A built-in five minute anti-short cycle (ASC) timer provides

short cycle protection of the compressor.

Component Sequencing Delays

Components are sequenced and delayed for optimum space

conditioning performance and to make any startup noise less

noticeable. There is a short delay between the blower motor

and the compressor start up.

Test Mode

The microprocessor control allows the technician to shorten

timing delays for faster diagnostics by removing the TEST

jumper located on the lockout board. It should be reinstalled

for normal operation after testing. The status LED will not be

illuminated during the TEST mode.

Resistance Heat Control

The resistance heat control module contains the appropriate

high-voltage control relays. Low voltage control signals from

the lockout board energize the relays in the resistance heat

module to engage backup resistance heat when necessary.

The lockout board offers a pass through W1 (1st Stage) and a

relay output for W2 (2nd Stage). See staging in sequence of

operation section.

Loop Pump Circuit Breakers

The loop pump(s) and HWG pump are protected by control

box mounted circuit breakers for easy wiring of pumps during

installation. Circuit breakers eliminate the need to replace

fuses.

Section 8: Controls

Safety Controls

The lockout board receives separate signals for high pressure,

low pressure, low load heat exchanger freeze, source heat

exchanger freeze, condensate overflow, and hot gas

temperature limit faults. Upon a continuous 30-second

measurement of all faults, except the high pressure fault, the

compressor operation is suspended. The high pressure fault is

immediate. The combination of LED(s) indicate each fault.

Once the unit is locked out (see fault retry below), an output

of 24VAC is energized on the “L” terminal for remote

indication of a fault at the thermostat.

Flow Switch - FS (If equipped - brazed plate only)

.

A flow switch ensures the source water maintains the

minimum required flow rate. This ensures that pumps are

working and water connections remain intact. The flow

switch will also trip when the source water begins to freeze,

providing additional protection. A Flow Switch is utilized on

units with a BPHE source coil. A Flow Switch is not included

on units utilizing a COAX source coil.

Electronic Condensate Overflow Protection (CO)

(If equipped - Packaged Units Only)

The control board utilizes an impedance sensing liquid sensor

at the top of the drain pan. When water touches the sensor,

CO fault occurs. If the fault is present for 30 continuous

seconds, the lockout board indicates a condensate overflow

fault has occurred.

If water touches the condensate overflow sensor for 30

continuous seconds, the compressor operation will be

interrupted. The control will go into fault retry mode. There

is no delay of switch monitoring at startup.

Low Pressure-LP:

If the low pressure switch is open

continuously for 30 seconds, the compressor operation will

be interrupted, and the control will go into fault retry mode.

At startup, the low pressure switch is not monitored for 30

seconds to avoid nuisance faults. (If the low pressure switch is

open before startup then the unit will not start upon

receiving an Y1 call and will lock out instead.)

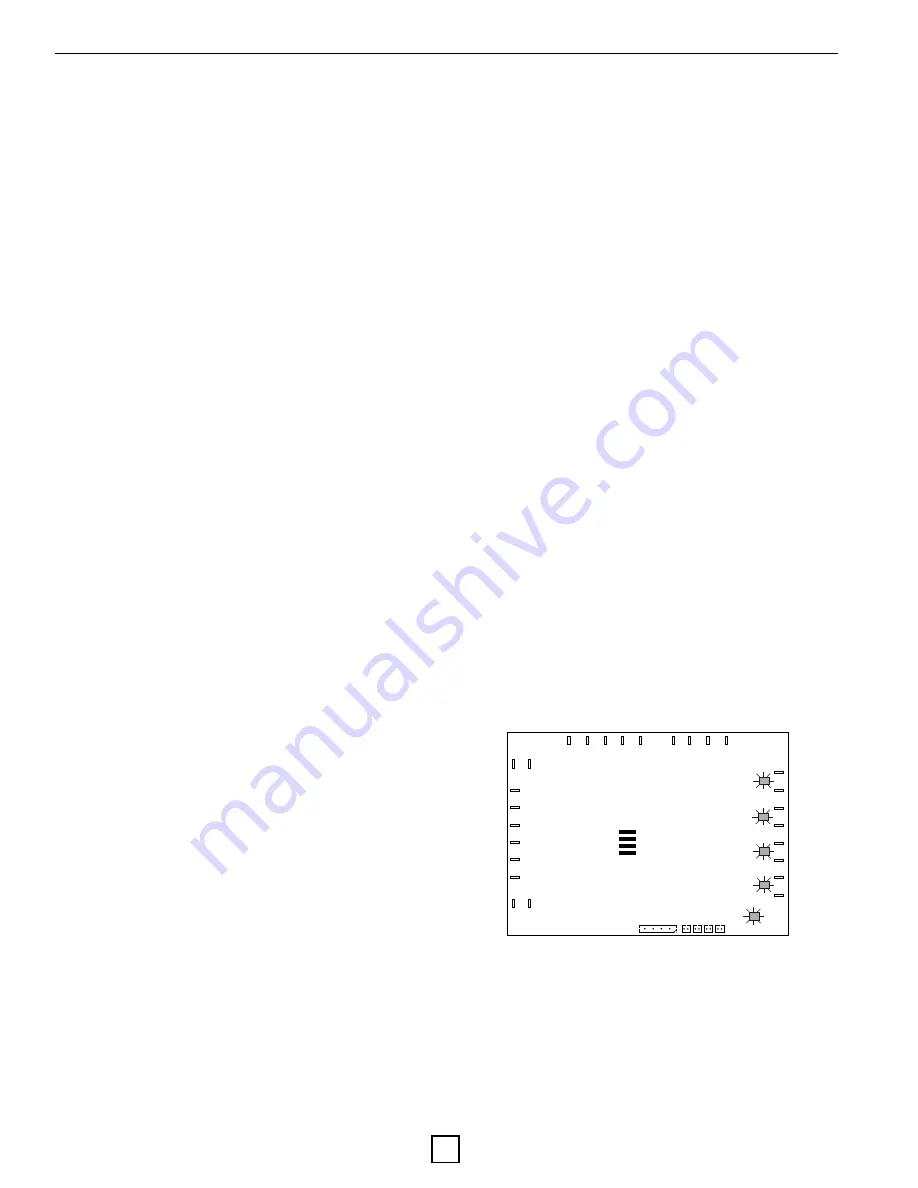

Lockout Board Layout

CC

HP

Lockout

Board

HWG W2 G W1 Y2 R_2 R_1 C_2 C_1

AFRZ

TEST

O/V

STATUS

LP

FS

CO

A

C

R

Y1

L

O O

CCG

1

CCG

UART 1 2 3 4

FSW

High Pressure-HP:

If the high pressure switch opens, the

compressor operation will be interrupted, and the control will

go into fault retry mode. There is no delay between the time

the switch opens and the board entering into fault retry

mode. There is also no delay of switch monitoring at startup.

(If the high pressure switch is open before startup then the

unit will not start upon receiving an Y1 call and will lock out

instead.)