L4478_a

19

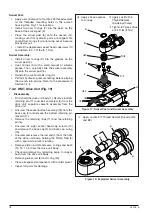

• Reassembly and Installation

In the following steps, coat all O-rings and

seals with silicone grease before installation.

Do not use excessive force when installing

the piston rod (3) in the following steps. Excessive force

may cause damage to these component and also may

damage the sealing faces within the wrench.

• Insert the O-ring (20) and grub screw (8) into the

relief shaft.

NOTE:

Ensure the grub screw (8) and O-ring (20)

have been installed after Loctite 577 has been

applied. Loctite must be fully cured before testing.

• Fit bush (5) and rod end seal (14) into the drive unit

body piston shaft (1)

• Insert the piston O-ring (16) into the lower groove

on the piston rod (3) followed by the piston cup

seal (13) into the upper groove. Insert the piston

rod (3) into the drive unit body (1).

• Apply threadlock to the Rod End (4) threads and

install into the Piston Rod (3), holding the Piston

Rod with a spanner to prevent rotation.

NOTICE

NOTICE

8

✴

20

✫

16

✫

13

✫

15

✫

2

18

17

14

✫

5

✫

11

4

�

�

6

12

3

�

10

✽⁂

1

7

9

19

✫

Apply ISO 10 grade oil to O-rings.

✽

Apply Loctite 243 Thread Sealant

Apply Loctite 577 Thread Sealant

Apply Threadlock

• Install the back cap thread O-ring (15) into the

groove in the back cap body (2).

• Attach the back cap (2), and secure with the eight

socket head cap screws after applying Loctite 243

Thread Sealant (10).

Tighten the socket head cap

screws to the following Torque values:

ο HMT1500 : 6 Ft/lbs [8 Nm]

ο HMT3500 : 14 Ft/lbs [19 Nm]

ο HMT7500 : 30 Ft/lbs [41 Nm]

• Place the bottom retaining pin lanyard (17) onto the

back cap and secure with the socket button head

cap (18).

• Fit the top retaining pin (6) and retaining ring (11).

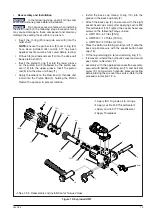

• If removed, reinstall the hydraulic swivel and swivel

post. Refer to Section 7.2.1.

• Assembly with the appropriate cassette assembly,

secured with bottom retaining pin (11) and ball end

screw (9); and perform hydraulic pressure testing

before placing the wrench into service. Refer to the

procedure in Section 7.2.6.

Figure 19: Exploded HMT

⁂•

See 7.3.2, Reassembly and Installation for Torque Values.

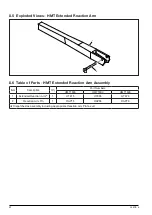

Summary of Contents for HMT Series

Page 2: ......

Page 44: ...2020 Enerpac Tool Group All Rights Reserved www enerpac com...