Installation and wiring

17

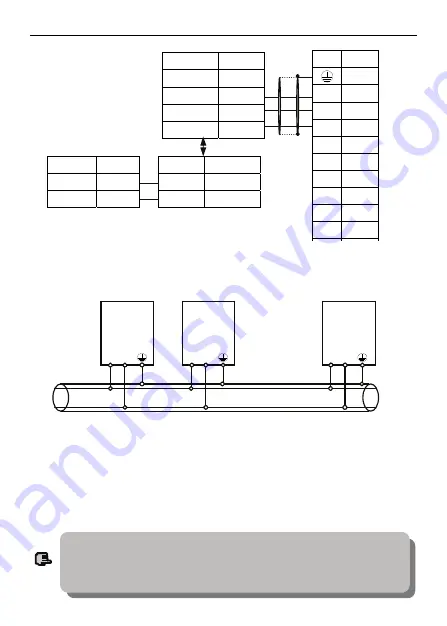

Fig. 3-10 RS485 communication wiring

(4) Multiple inverters can be connected together per RS485 and 31pcs inverter

can be connected together at most. Communication system is more prone to

disturbance as connected inverters increasing, following wiring is recommended:

Fig. 3-11 Recommended wiring for multiple inverters communication

(all inverters and motors well earthed)

Normal communication still not available if using above wiring, can try to take

following measure:

1>

Provide separate power supply for PLC (or upper machine) or isolate its

power supply.

2>

Apply magnetic circle on the communication wire.

3>

Reduce inverter carrier wave frequency properly.

EDS300

CPU board

Mainframe

485A

EDS300

CPU board

Submachine

EDS300

CPU board

Submachine

…

…

485B

485A 485B

485A 485B

Terminal Name

Negative end

B

Positive end

A

Signa

Pin No.

Shell

RXD 2

TXD 3

TXD 3

GND 5

DTR 4

DSR 6

RI 9

CD 1

RTS 7

Terminal Name

Power supply

+5V

Sending TXD

Receiving RXD

5V Grounding

GND

Name Terminal

B

Negative

A

Positive

232/485 Converter

Shielded

cable

(1) When form the network only by inverters, you must set local address parameter F2.15

of the mainframe EDS300 to 0.

(2) For programming of RS485 interface

,

please refer to chapter 7 MODBUS

communication protocol.

Note

ENC