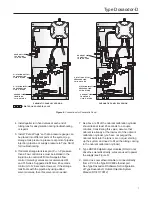

Figure 10.

Two Way Injection Solenoid Valve - Maintenance

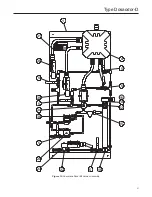

Figure 9.

Odorant Filter - Maintenance

7

40A

40B

40C

39G

39H

39H

39F

39F

39E

39D

39C

39B

39A

40D

40E

40F

40G

40H

40j

40k

123

LIqUID INLET

LIqUID OUTLET

• Stop Odorant Recovery Cycle after about 15

seconds (depending on the installation conditions)

and eventually repeat the procedure if needed.

• Select gas wash time.

• Run gas wash cycle.

• The cycle will be terminated when the Gas Wash

cycle time will expire.

• Put the system in disable mode and turn it off

before maintenance operations.

At this point all valves of the system have to be closed

and you can perform maintenance operations on the

involved parts.

After completing all operations, to restart the system

open the system valves, turn ON the odorizer, reset the

existing alarms and put the system in AUTO (MANUAL

or MINIMUM RATE).

Injection Solenoid Valve Cleaning with

Liquid Odorant (Injector Flush)

NOTICE

During the washing operation with

natural gas the control activates both

injectors at the same time (to increase

the drying process), during injector

flush just the selected injector is

activated. This allows the system to

increase the pressure for cleaning the

dirty injector and reduce potential over

odorization issues.

For injector selection, please refer

to Type Dosaodor-D Software for

Configuration of Type Dosaodor-D

Odorant Injection System

Manual (D103117X012).

19

Type Dosaodor-D