4

INSTALL

CLOSER

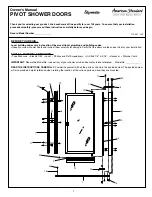

(Images shown are for

a Left Hand installa-

tion. A Right Hand

installation would be

on the opposite side

shown.)

3

1/8”

Tools needed:

2”

x 3

x 1

x 2

x 1

x 1

5/8”

1.

Position the base (T) onto the door jamb by

touching the front of the base to the back

of the hinge rail (or as close as possible),

position and center the base 2” below the

window opening. Mark the hole locations

on the door jamb.

2.

Drill holes in the door jamb at the marked

locations and attach the base to the door

jamb with two (2) 2” screws (W) from the

green bag into the two holes closest to the

interior of the house.

1.

Place hold open washer (BB) from the green

bag on closer rod.

2.

Pin the closer (S) in place using the short

pin (Z) in the jamb bracket (U) and the long

pin (Y) in the door bracket (V).

3.

Pull on the closer so the rod extends

slightly. Snap the orange preload clip (AA)

from the green bag over the rod. The clip

should be pinched tight between the closer

cylinder body and the opposing bumps on

the closer rod.

1.

Open the door and then let it close. Note the speed at which the

door closes.

2.

Use a screwdriver to adjust the closer to the desired speed:

For a faster closing speed, turn the adjustment screw to the left

(counterclockwise).

For a slower closing speed, turn the adjustment screw to the

right (clockwise).

3.

Test the speed at which the door closes after each adjustment.

1.

Close the storm door. Swing the closer

assembly over until the door bracket (V) is

resting against the storm door and appears

level. Mark hole locations on the door

frame.

2.

Drill holes 5/8” deep and attach the closer

door bracket to the door frame through

the two pre-drilled holes using two (2) 5/8”

screws (X) from the green bag.

1.

Attach the arm (U) to the base by inserting

the tabs on the arm into the slots in the

base. Fasten with a 2” screw (W) from the

green bag.

Do not drill completely through door. This will create an

unnecessary hole in the door and may cause water and

air infiltration.

caution

ADJUST

CLOSING

SPEED OF

DOOR

(Closer image is for

reference only)

4

Tools needed:

HInge raIl

RIEL ABISAgRADO

MOnTanT à

CHarnIèreS

OPPOSITe vIeW

OTRO PUNTO DE VISTA

vue De FaCe

FrOnT vIeW

VISTA FRONTAL

vue avanT

AA

BB

U

U

T

S

S

Z

Y

V

V

AA

W

W

W

a

b

c

d

a

Storm door will close more quickly when entry door is open. To achieve the proper closing speed, you will need to adjust

the closer(s) using the built-in adjustment screw. Check for safe closing speed with your entry door in both the closed and

the open position. To prevent injury, make sure people and/or pets are completely through the opening before allowing

the storm door to shut freely.

warning

S

V

2”

!

!

1/2”

1/2”

1”

1 1/2”

2”

1 1/2”

5/8”

5/8”

X

X

!

!

1/2”

1/2”

1”

1 1/2”

2”

1 1/2”

5/8”

5/8”

green bag /

BOLSA VERDE

/ SaC verT

i

vIeW

i

vIeW

i

vIeW

i

vIeW

i

vIeW

#8

#10

#12

#6

3/4” Machine Pan Painted

1/2” SMS Pan

1/2” SMS Pan Painted

1/2” SMS Flathead

1/2” Self-Drill Pan

1/2” Self-Drill Pan Painted

3/4” Machine Flathead

7/8” Machine Pan Painted

1” SMS Pan

1” SMS Pan Painted

1” Machine Pan Painted

1-1/2” Machine Flathead

1-1/2” Machine Flathead

2” SMS Pan Painted

5/8” SMS Pan Painted

1-1/4” SMS Pan

#8

#10

#12

#6

3/4” Machine Pan Painted

1/2” SMS Pan

1/2” SMS Pan Painted

1/2” SMS Flathead

1/2” Self-Drill Pan

1/2” Self-Drill Pan Painted

3/4” Machine Flathead

7/8” Machine Pan Painted

1” SMS Pan

1” SMS Pan Painted

1” Machine Pan Painted

1-1/2” Machine Flathead

1-1/2” Machine Flathead

2” SMS Pan Painted

5/8” SMS Pan Painted

1-1/4” SMS Pan

#8

#10

#12

#6

3/4” Machine Pan Painted

1/2” SMS Pan

1/2” SMS Pan Painted

1/2” SMS Flathead

1/2” Self-Drill Pan

1/2” Self-Drill Pan Painted

3/4” Machine Flathead

7/8” Machine Pan Painted

1” SMS Pan

1” SMS Pan Painted

1” Machine Pan Painted

1-1/2” Machine Flathead

1-1/2” Machine Flathead

2” SMS Pan Painted

5/8” SMS Pan Painted

1-1/4” SMS Pan

#8

#10

#12

#6

3/4” Machine Pan Painted

1/2” SMS Pan

1/2” SMS Pan Painted

1/2” SMS Flathead

1/2” Self-Drill Pan

1/2” Self-Drill Pan Painted

3/4” Machine Flathead

7/8” Machine Pan Painted

1” SMS Pan

1” SMS Pan Painted

1” Machine Pan Painted

1-1/2” Machine Flathead

1-1/2” Machine Flathead

2” SMS Pan Painted

5/8” SMS Pan Painted

1-1/4” SMS Pan

Y

X

W

Z

!

!

1/2”

1/2”

1/2”

1”

1 1/2”

2”

1 1/2”

5/8”

5/8”