03/2011 - Art. Nr. 4200 1016 4000C

23

Service

Maintenance

Burner and boiler servicing must only

be carried out by a professionally

qualified heating engineer. The

system operator is advised to take

out a service contract to guarantee

regular servicing.

Please observe the following points:

• Disconnect the electrical supply before

carrying out any maintenance or

cleaning work.

Checking the exhaust gas

temperature

• Check the flue gas temperature at

regular intervals.

• Clean the boiler if the flue gas

temperature is more than 30°C above

the value measured at the time of

commissioning.

• To simplify the check, use a flue gas

temperature indicator.

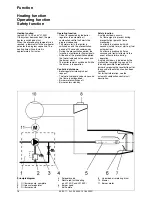

Burner maintenance positions

• After removing the screws

1

, the

equipment plate can be hung in two

maintenance positions.

Position 1

For example, for replacing the nozzle

rod:

• Loosen oil connection

12

• Disconnect connector

9

• Remove electrode block

10

1

Fastening screws

2

Mounting opening

3

Ignition transformed

5

Oil combustion system

6

Oil burner pump

7

Nozzle rod

8

Flame monitor

9

El. connection for nozzle rod

10 Electrode block

11 Regulating screw for combustion

head

12 Oil connection, nozzle rod

13 Nozzle

14 Baffle plate

15 Blower wheel

Maintenance on the burner

Maintenance position 1

• Check oil supply components (tubes,

pumps, oil feed tube) and their con-

nections for leaks or signs of wear,

replace if necessary.

• Check electrical connections and con-

nection cables for damage, replace if

necessary.

• Check pump filter and clean if neces-

sary.

Maintenance position 2

• Clean blower wheel and housing and

check for damage.

• Check and clean the combustion

head.

• Remove baffle plate.

• Replace oil nozzle.

• Check ignition electrodes, readjust or

replace as necessary.

• Fit combustion head. Observe adjust-

ment dimensions (see page 21).

• Fit burner.

• Start burner, check flue gas data,

correct burner settings if necessary.

• Perform flame monitor function check

(see page 22).

Position 2

For instance, for replacing the nozzle

and blower wheel . This position avoids

having to empty the nozzle rod when the

nozzle is changed.

Blower wheel assembly

Observe the positioning diagram below

when replacing the motor and blower

wheel. The inside flange

A

of the blower

wheel must be fitted at the same level as

the equipment plate

B

. Insert a straight

edge between the wing of the blower

wheel and set

A

and

B

to the same

height, tighten the set screw on the

blower wheel (maintenance position 2).

en

Réinitialisation de l’indicateur de

maintenance

Le symbole de maintenance apparaît

sur l’afficheur du coffret après 30 000

démarrages. C’est pourquoi il est

nécessaire, après chaque entretien, de

réinitialiser le compteur de

maintenance. Pour ce faire, appuyer

pendant au moins 9 secondes sur le

bouton de déverrouillage du coffret.