Page 13 of 47

Catalog #91001, 91003, 91004, 91005, 91007, 91009

Rev. 9/06 - RS/mc

©2006 Edelbrock Corporation

Brochure #63-0282

There are 3 types of Digital Inputs. You must correctly identify your inputs before proceeding!!!

Logic signal

Channels 1 and 6 are configured to measure signals that switch between a high (12 or 5 volts) and low (ground) voltage by themselves.

This may be a tach. signal, a signal generated from another electronic device (1TL or CMOS level), an injector input etc.

WARNING!!!

Do not connect any digital input directly to an ignition coil as the electrical noise may cause improper operation of

QwikData or damage the unit

(Use MSD tachometer adapter #8132 to connect to the negative side of a coil).

Grounding Type Switch

Channels 2,3, and 5 are configured with a pull-up resistor so that a grounding type switch can be read, e.g. when using one of our

wheel speed sensors the normal reading is 12 V due to the pull-up resistor, then the signal goes to ground level when the switch passes

by the magnet.

Low to high signal

Channel Four (4), is configured with a pull-down resistor in the basic

QwikData unit to allow it to read signals with either the presence or absence

of 12V. e.g. when monitoring an ignition switch the signal is either a 12V

signal or an open circuit (not ground) when the switch is off. Digital Input

Channels can be changed to be any of the 3 types listed above by changing

internal jumper settings. See the

“QwikData Jumper Configuration” on

page 46.

Proceed with caution when changing the digital channel

Jumper settings

.

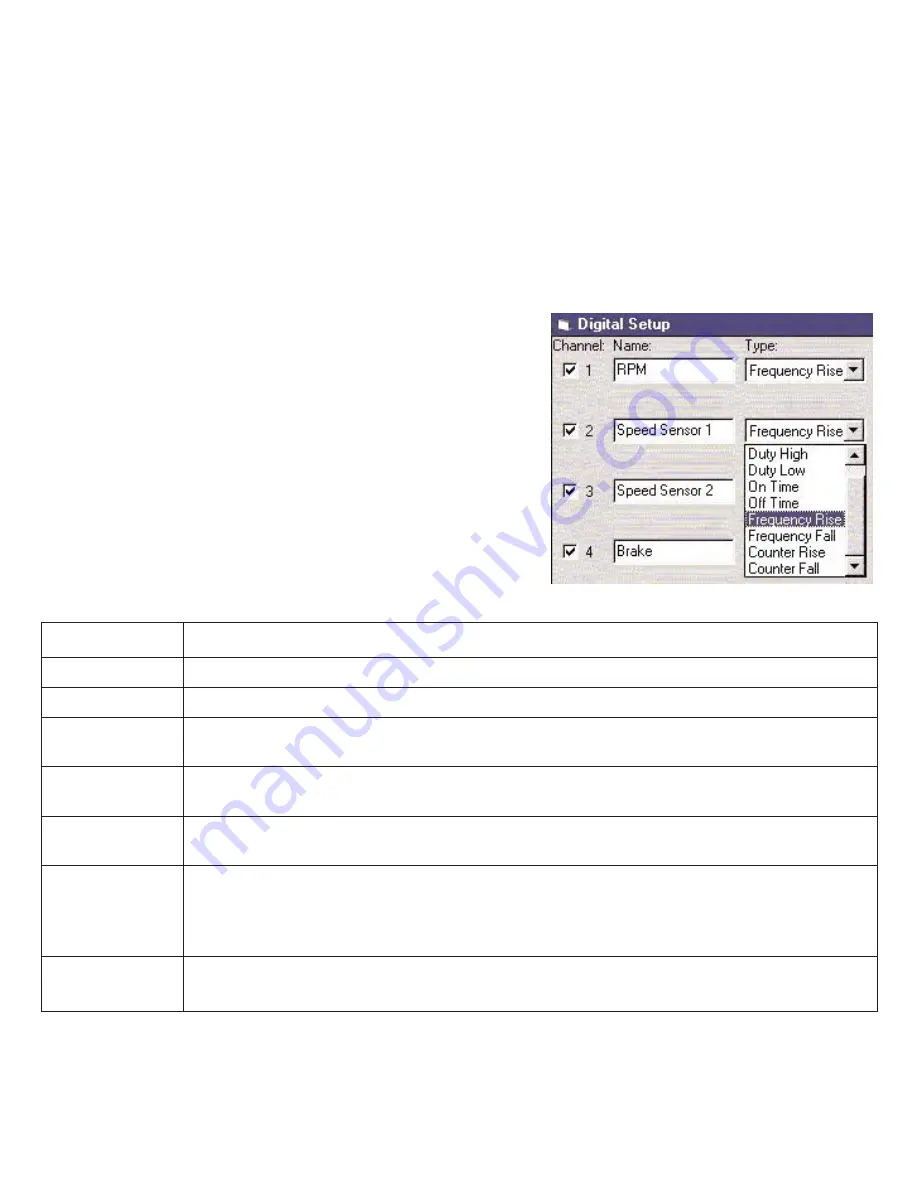

Type: Select Input type from pull-down menu.

Pure Digital

Select when you simply want to .determine status of a two state input (e.g. Brake light on/off).

Duty High

Used mostly for computer cars, E.g. to measure the percentage of time an input (e.g. injectors) is high.

Duty Low

Used mostly for computer cars, E.g. to measure the percentage of time an input (e.g. injectors) is low.

On Time

Used mostly for computer cars, E.g. to measure the absolute time (in milliseconds) an input (e.g. injectors) is

high.

Off Time

Used mostly for computer cars, E.g. to measure the absolute time (in milliseconds) an input (e.g. injectors) is

low.

Frequency Rise

Used to measure the frequency of an input (e.g. Tach, signal, wheel speed sensor) by measuring the rising edge

of a signal. The units for frequency are Hz x 100.

Frequency Fall

Used to measure the frequency of an input (e.g. Tach. signal, wheel speed sensor) by measuring the falling edge

of a signal. The numbers generated by using this setting are usually the same as those measured by selecting

“Frequency Rise”, but this setting may be preferable with certain types of signals (e.g. those with lots of

electrical noise). The units for frequency are Hz x 100.

Counter Rise

Used to count the number of transitions from low to high of a variable. This is an alternate setting for inputs

such as “lap beacons”.

Summary of Contents for QwikData 91001

Page 51: ......