19

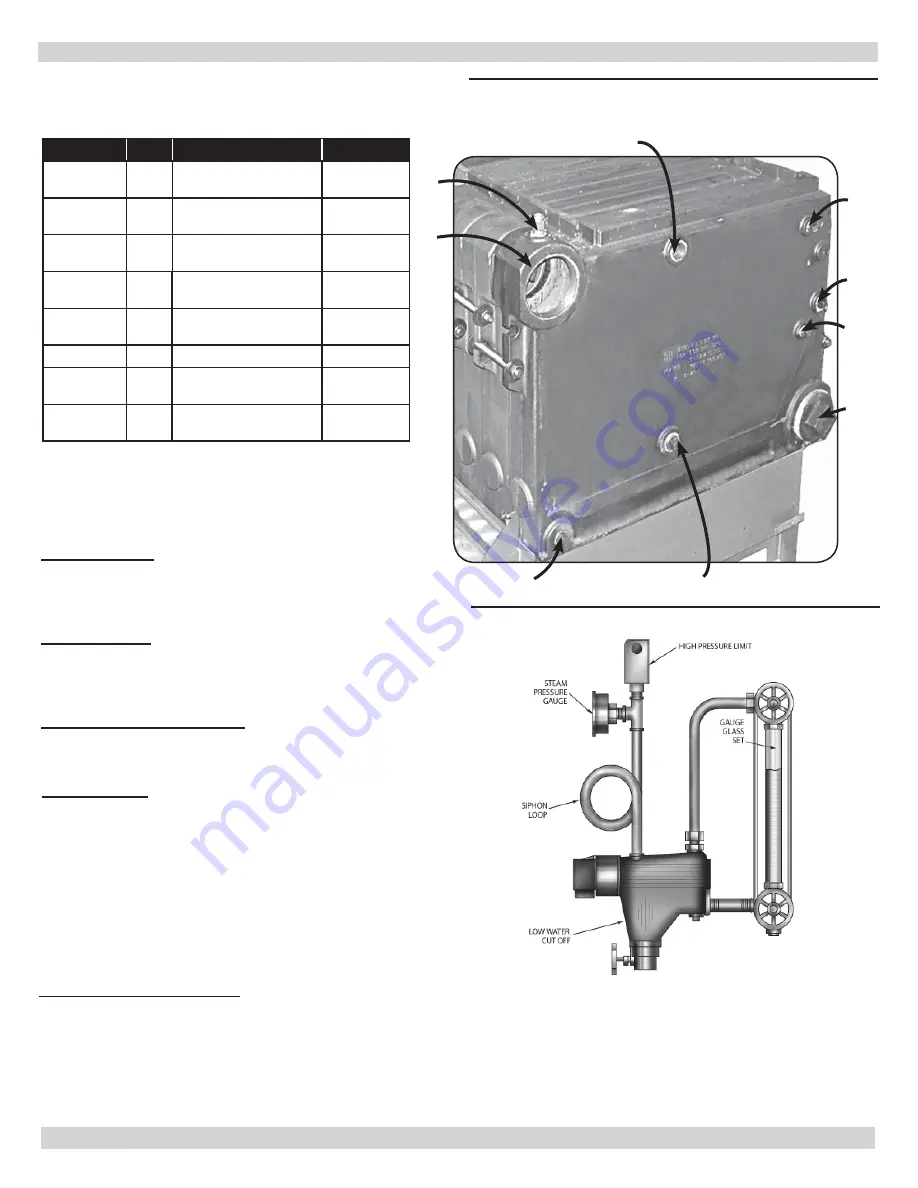

Illustration shows the end section and the various tap-

pings provided. Tappings are the same in both right

and left end sections.

OPENING

SIZE

STEAM

WATER

A

4”

Supply and Return

Supply and

Return

B

½”

Primary LWCO and

Gauge Glass Set

Plugged

C

¾”

Drain, Left End

Drain, Left

End

C

¾”

Drain, Right End

Drain, Right

End

D

½”

Plugged

Limit Con-

trol

E

1”

Accessories

Accessories

*F

1”

Safety Valve

Safety Relief

Valve

G

¾”

Plugged or Electronic

(Probe Type) LWCO

Plugged

*If opening F is to be used for something other than

the Safety Valve or Safety Relief Valve, or the Safety/

Relief valve is larger than 1”, the Safety/Relief Valve

must be installed in the Header Piping as near the

boiler as possible

A

B

A

B

C

D

E

F

G

BOILER TRIM

Following controls are supplied as standard equipment.

Details of their function and operation will be found in

section on Controls and Adjustments.

WATER TRIM

1. Water temperature high limit control

2. Combination temperature - pressure gauge

3. Safety relief valve (30 psi)

WATER TRIM ASSEMBLY

Locate water trim controls per chart and illustration

above.

STEAM TRIM

1.

Low Water Cut-Off (mounted externally) with blow-off

valve

2.

High Pressure Limit Control

3.

Pressure Gauge

4.

Water Gauge Glass Set

5.

Siphon Loop

6.

Safety Valve (15 psi..)

NOTE:

No shutoff of any description shall be placed between

the pressure relief valve and the boiler, or on discharge

pipes between such safety valves and the atmosphere.

Installation of the pressure relief valve shall conform

to the requirements of the ANSI/ASME Boiler and

Pressure Vessel Code, Section IV.

STEAM TRIM ASSEMBLY

Assemble Steam Trim, Low Water Cut-Off, High

Pressure Limit Control, Pressure Gauge, Water Gauge

Glass Set and Siphon Loop, as shown in Figures

30. See Illustration and Chart above for location of

controls.

Figure #30

WATER LEVEL

29” TO FLOOR

TAPPINGS

Figure 29

Figure 30