28141 Rev A 10-27-06

7

Soot behaves as an insulator and impairs good

heat transfer. Stack temperature will increase,

and the overall efficiency will decrease. As a

means of avoiding this problem, it is advisable to

adjust the air supply to provide no more than a

trace smoke spot on the Bacharach Scale.

NOTE: SIDEWALL VENTED MODELS SHOULD

BE SET UP TO DELIVER ZERO (0)

SMOKE.

BEFORE OPERATING THE FURNACE

CHECK BURNER ALIGNMENT WITH

COMBUSTION CHAMBER. THE END

CONE OF THE AIR TUBE MUST BE

CENTRED TO THE ACCOMODATING

RING PROVIDED IN THE DESIGN OF

THE COMBUSTION CHAMBER. ADJUST

AS NECESSARY.

See the Venting Instructions included in the Vent

Kits for set-up details for sidewall vented

furnaces.

16. BURNER ELECTRODES

Correct positioning of the electrode tips with

respect to each other, to the fuel oil nozzle, and to

the rest of the burner is essential for smooth light

ups and proper operation. Refer to the oil burner

instructions shipped with the furnace for electrode

specifications.

NOTE: Beckett AF Series Burner electrode

specifications have been revised. They should be

adjusted to be 5/16” above the nozzle centerline.

Use of Beckett’s “Z” gauge is recommended

17. BURNER PRIMARY CONTROL

The furnace is equipped with a primary

combustion control, sometimes refer to as the

burner relay or burner protector relay, which uses

a light sensing device (cad cell) located in the

burner housing, to monitor and control

combustion. Over time, dust or combustion

residuals can build up on the lens of the cad cell

impairing its response to the flame. The cad cell

should be checked for cleanliness and proper

alignment if the primary control frequently shuts

down combustion.

ALL FURNACE CONTROLS ARE

SENSITIVE AND SHOULD NOT BE

SUBJECTED TO TAMPERING. IF

PROBLEMS PERSIST, CALL YOUR

SERVICE CONTRACTOR.

18. COMBUSTION CHAMBER

This furnace is equipped with a high quality

cerafelt combustion chamber. It is held in place by

a support bracket and stainless steel retaining

band and clamp.

CHECK THE ALIGNMENT OF

THE COMBUSTION CHAMBER AND OIL

BURNER BEFORE FIRING. IT IS POSSIBLE

FOR THE COMBUSTION CHAMBER TO SHIFT

IF SUBJECTED TO ROUGH HANDLING

DURING TRANSIT

. The combustion chamber

should be inspected for damage or carbon build

up whenever the oil burner is removed for repairs

or routine maintenance.

DO NOT START THE BURNER UNLESS

THE BLOWER ACCESS DOOR IS

SECURED IN PLACE.

19. CIRCULATING AIR BLOWER

The BCL and BFL furnaces are equipped with

either direct drive or belt drive blower systems.

Direct drive blower speed adjustments are not

normally required in properly sized extended

plenum duct systems. The motor RPM and air

CFM delivery will vary automatically to

accommodate conditions within the usual range of

external static pressures typical of residential duct

systems. Under-sized duct systems may require a

higher blower speed to obtain a reasonable

system temperature rise. Some older duct

systems were not designed to provide static

pressure. They typically feature special reducing

fittings at each branch run and lack block ends on

the trunk ducts. These systems may require

modification to provide some resistance to the

airflow to prevent over- amping of the direct drive

blower motor. Selecting a lower blower speed

Summary of Contents for BCL

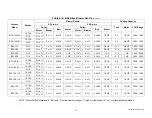

Page 23: ...28141 Rev A 10 27 06 23 TABLE B 1 BECKETT AND RIELLO CHIMNEY VENTED WIRING DIAGRAM BCL S BFL ...

Page 24: ...28141 Rev A 10 27 06 24 TABLE B 2 BECKETT AND RIELLO DIRECT VENT WIRING DIAGRAM BCL S BFL ...

Page 29: ...29809 Rev A 10 19 2006 29 ...

Page 32: ...29809 Rev A 10 19 2006 32 ...

Page 36: ...29809 Rev A 10 19 2006 36 ...

Page 41: ...28141 Rev A 10 27 06 NOTES ...

Page 42: ...28141 Rev A 10 27 06 ...

Page 43: ...28141 Rev A 10 27 06 ...