28141 Rev A 10-27-06

6

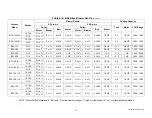

Furnace Power Requirements

Furnace

Model

Volts

AC

Amps

Phase

∅

Cycles

Hz

BCL (S)

120

15

1

60

BFL 120

15

1

60

BCL-170/190 120 15 1

60

BCL-200/225 120 20 1

60

Accessories requiring 120 VAC power sources

such as electronic air cleaners and humidifier

transformers may be powered from the furnace

circuit, but should have their own controls. Do not

use the direct drive motor connections as a power

source, since there is a high risk of damaging the

accessories by exposure to high voltage from the

auto-generating windings of the direct drive motor.

Thermostat wiring connections and air

conditioning contactor low voltage connections

are shown in the wiring diagrams in Appendix B.

Some micro-electronic thermostats require

additional controls and wiring. Refer to the

thermostat manufacturer's instructions.

The thermostat should be located approximately 5

feet above the floor, on an inside wall where there

is good natural air circulation, and where the

thermostat will be exposed to average room

temperatures. Avoid locations where the

thermostat will be exposed to cold drafts, heat

from nearby lamps and appliances, exposure to

sunlight, heat from inside wall stacks, etc.

The thermostat heat anticipator should be

adjusted to the amperage draw of the heating

control circuit as measured at the "R" and "W"

terminals of the thermostat. To reduce the risk of

damaging the heat anticipator, do not measure

this current with the thermostat connected to the

circuit. Measure the amperage by connecting an

ammeter between the two wires that will connect

to the thermostat "R" and "W" terminals.

11. HUMIDIFIER

A humidifier is an optional accessory available

through most heating supplies outlets. Installation

should be carried out in accordance with the

humidifier manufacturer's installation instructions.

Water or water droplets from the humidifier should

not be allowed to come into contact with the

furnace heat exchanger. Do not use direct drive

motor connections as a source of power for 120

VAC humidifiers and humidifier transformers.

12. PIPING INSTALLATION

The entire fuel system should be installed in

accordance with the requirement of CAN/CSA B-

139, and local regulations. Use only an approved

fuel oil tanks piping, fittings and oil filter.

In the United States the installation must be in

accordance with NFPA No. 31 and local codes

and authorities.

Install the oil filter as close to the burner as

possible. For further details of the oil supply tank

and piping requirements, please refer to the

instructions and illustrations in the oil burner

instructions shipped with the furnace.

13. OIL FILTER

All fuel systems should include an oil filter

between the fuel oil storage tank and the oil

burner. When using an oil burner nozzle smaller

than 0.65 U.S. Gallons Per Hour, install an

additional 7 to 10 micron filter as close as

possible to the oil burner.

14. OIL BURNER NOZZLES

The BCL (S) and BFL models are certified for

multiple firing rates, ranging from 80,000 to

145,000 Btu/h. By manipulating the oil burner

nozzle, flame retention head, static plate and

temperature rise. The BCL 190 model series is

certified for multiple firing rates ranging from

170,000 to 225,000 Btu/h. By manipulating the oil

burner nozzle, and temperature rise, these

furnaces may be fired at an ideal rate for a wide

range of structures. Refer to Table A-1, and the

furnace rating plate to determine the proper

combinations.

15. OIL BURNER ADJUSTMENT

The burner air supply is adjusted to maintain the

fuel to air

ratio

to obtain ideal combustion

conditions. A lack of air causes "soft" and "sooty"

flames, resulting in soot build-up throughout the

heat exchanger passages. Excess combustion air

causes a bright roaring fire and high stack

temperatures resulting in poor fuel efficiency. The

BCL and BFL furnaces operate most efficiently

with a No. 1 smoke spot on the Bacharach Scale.

This is not necessarily the optimum setting;

however, because dust will inevitably build up on

the air moving components of the oil burner

assembly. This will result in decreased air supply

with the potential result of soot building up in the

flue gas passageways of the heat exchanger.

Summary of Contents for BCL

Page 23: ...28141 Rev A 10 27 06 23 TABLE B 1 BECKETT AND RIELLO CHIMNEY VENTED WIRING DIAGRAM BCL S BFL ...

Page 24: ...28141 Rev A 10 27 06 24 TABLE B 2 BECKETT AND RIELLO DIRECT VENT WIRING DIAGRAM BCL S BFL ...

Page 29: ...29809 Rev A 10 19 2006 29 ...

Page 32: ...29809 Rev A 10 19 2006 32 ...

Page 36: ...29809 Rev A 10 19 2006 36 ...

Page 41: ...28141 Rev A 10 27 06 NOTES ...

Page 42: ...28141 Rev A 10 27 06 ...

Page 43: ...28141 Rev A 10 27 06 ...