66

APPENDIX A - CONTROL MODULE

User Interface Display

Explanation

Installer Menu

Boiler Status

S T A T U S

▲

I g n i

t

i o n

A t t e m p t s

S u c c e s f u l

4 2 6 7

F a i

l e d

2 1

▼

Control module logs successful and failed ignition attempts.

Information accessed in ‘Ignition Attempts’ Screen as shown.

Ignition attempts are stored in non-volatile memory and are

retained in event of power failure.

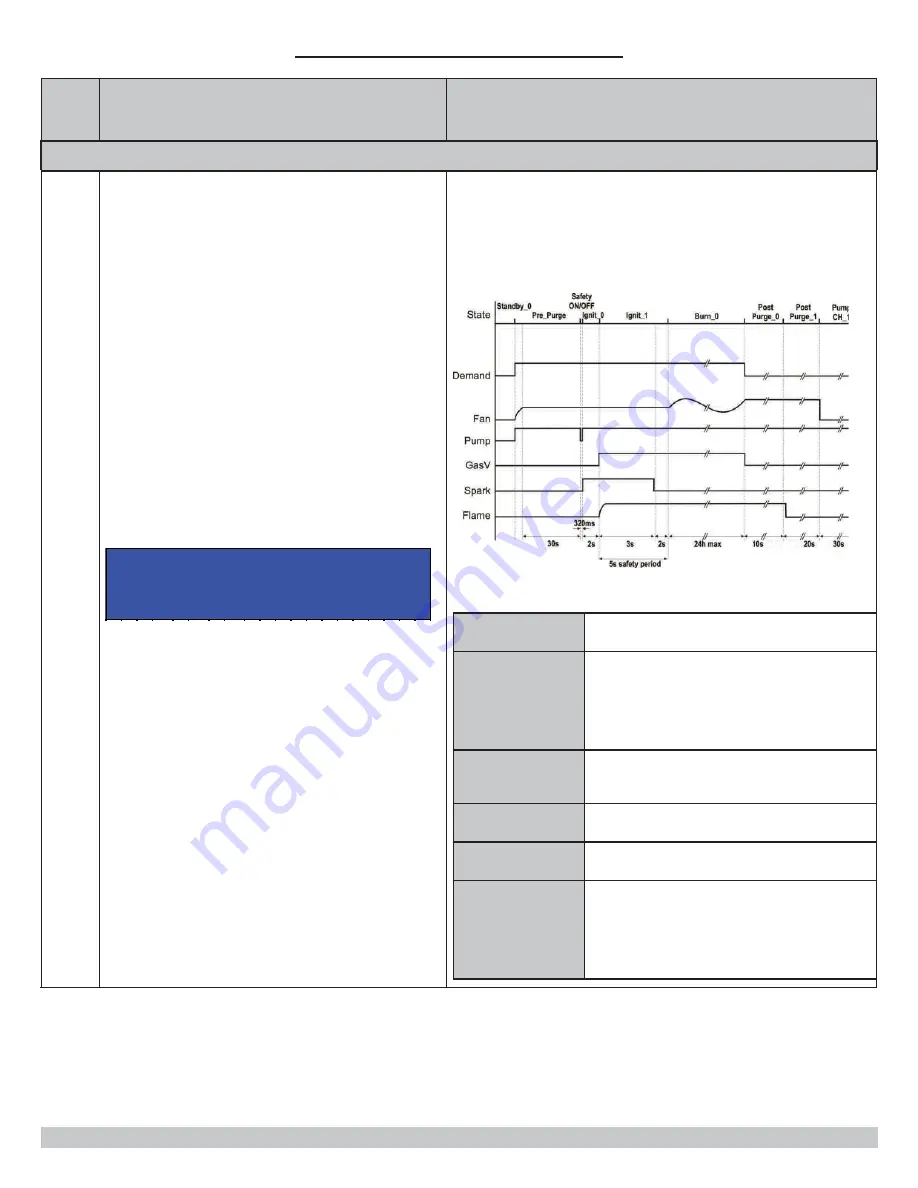

Figure A-1 Typical Ignition Cycle

Following control features are implemented to ensure safe and

reliable operation of Combustion System:

False Flame

Detection

If fl ame is detected at end of pre-spark

period (Ignit_0) than lockout will occur.

Re-ignition

If at end of safety period no fl ame detected

control will go to post-purge removing

unburned gas. Re-ignition attempt started

following same cycle. Number of re-ignition

attempts limited to 4 after which lockout

occurs.

Intermittent

Operation

Boiler can be fi ring continuously for 24

hours. Burner switched off and restart

sequence follows.

Flame out too

late

If fl ame detected after post purge lockout

follows.

Safety relay test In Safety ON/OFF state correct operation

of safety relay is proved before ignition.

UL3563 High

Limit Tempera-

ture Device

Boiler comes equipped with UL353

approved temperature high limit device.

Gas Valve de-energized when supply

temperature exceeds 203°F lockout

follows.

Summary of Contents for 075 97gb

Page 56: ...56 14 WIRING DIAGRAM 14 1 Connection Diagram ...

Page 57: ...57 14 WIRING DIAGRAM 14 2 Schematic Diagram of Ladder Form ...

Page 73: ...73 ...

Page 74: ...74 ...

Page 75: ...75 ...