Installation, Operation and Parts Manual

EE-65A.40T

11

3.5 Technical data

Rated load capacity

4000KG

Full rise time with load

≤60s

Full lowering time with load

≤30s

Hydraulic pressure

22-24MPa

Pneumatic pressure

6-8 bar

Oil Volume

18L

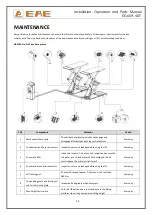

INSTALLATION INSTRUCTIONS

4.1 Preparations before installation

4.1.1 Space requirements.

Refer to 3.3 for the dimensions of the lift. There must also be a clearance of at least 1 meter between the lifting platform and fixed

elements (e.g. wall) in all lifting positions. There must be sufficient space at the ends of the lifting platform for driving vehicles on and off.

To stop vehicles colliding with the ceiling, it is advisable to fit an overhead light barrier in low ceiling buildings.

4.1.2 Foundations and connections

The user must have the following work performed before erecting the lift.

Construction of the foundation following consultation with the manufacturer’s customer service or an authorized service agent.

Routing of the wiring to the installation location. The user must provide fuse protection for the connection. Requirements for

power supply cable of the installation site: at least 2.5mm

2

wire core for 3Ph power and 4.0mm

2

wire core for 1Ph power.

Attention: electrical system connection must be done by licensed technicians.

Routing of the compressed air connection to the installation location.

Refer also to the corresponding information in the operation instructions.

4.1.3 Foundations preparations

Indoor installation only.

There must also be a clearance of at least 1 meter between the lifting platform and fixed elements (e.g. wall) in all lifting positions. There

must be sufficient space for driving vehicles on and off.

C20/25 concrete base with strength more than 3000psi, Minimum thickness of 150mm.

Surface: Horizontal and even (Gradients max. 0.5 %)

Newly built concrete ground must be older than 20days.

In mm.