Installation, Operation and Parts Manual

EE-65A.40T

20

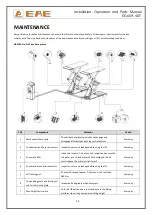

Turn on the power switch

Push UP button

Motor drives the gear pump work

The lift is raised

Cylinder piston drives the platform move up

Push the DOWN I button

The lift is lowered

Push the DOWN II button

Stop lowering at safety height

5.3 Flow chart for operation

5.4 Operation instructions

To avoid personal injury and/or property damage, permit only trained personnel to operate the lift. After reviewing these

instructions, get familiar with lift controls by running the lift through a few cycles before loading vehicle on lift. Always lift the

vehicle using both platforms. Never raise just one end, one corner or one side of vehicle.

Raise the lift

Make sure vehicle is neither front nor rear heavy and center of balance should be centered over the lift.

1. Make sure that you have read and understood the operation manual before operation.

2. Drive and park the vehicle midway between two platforms.

3. Place the four rubber pads under the pick-up points of the vehicle and ensure car’s gravity have fallen on the rubber pads.

4. Push the UP button on the control box until rubber pads have touched the pick-up points of vehicle.

5. Keep on pushing the UP button to lift the vehicle a bit off from the ground and check again that the vehicle is in a safe position

6. Push the safety lock button and “emergency stop” .Check again the stability of the vehicle before performing maintenance or repair work.

Lower the lift

When lowering the lift pay careful attention that all personnel and objects are kept clear.

1. Switch on.

2. Push the DOWN I button to lower the lift. It will stop lowering at safety height.

3. Push DOWN II button to continue lowering the platforms. Alarming buzz will be heard.

4. Remove rubber pads and drive the vehicle away

Raising

Lowering

Turn on the power switch