Installation, Operation and Parts Manual

EE-65A.40T

23

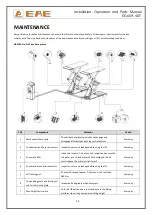

POS.

Components

Methods

Period

8

Safety lowering limit switch

Push the DOWNI button. Inspect and ensure the lifting

platform stops lowering at safety height and then push

DOWN II button to have the platform fully lowered.

Every day

9

Control buttons

Check if control buttons work as "hold- to -run " and

check if they work as the function indicated.

Every day

10

Solenoid unloading valve

Inspect if the valve leaks or not. Clean or change the valve

if it leaks.

Every day

Lifting platform

Check and adjust the synchronization of lifting platforms.

Ensure both platforms ascend and descend

synchronously.

Every day

11

Expansion bolts

Check with torque spanner. For M18 bolt ,the torque is no

less than 80N.m / For M16, the torque is no less than

60N.m

Every 3 months

12

Upside and downside sliders

Add grease to ensure smooth running.

Every 3 months

13

Joint shafts

Add grease into the oil cups.

Every 3 months

Whole Lift

Running the lift for several cycles with and without rated

load. The lift can run steadily and smoothly with no

abnormal noise.

Every 3 months

Hydraulic oil

Change the oil 6 months after initial use and once per

year thereafter. Inspect and change the oil if it becomes

black or there is dirt in the oil tank.

Every year

If users stick to the above maintenance requirements, the lift will always keep a good working condition

and its service life could be extended.