DUPLOMATIC

E.M.6427 RELEASE 7.1 05-03

6427071-230-en 17

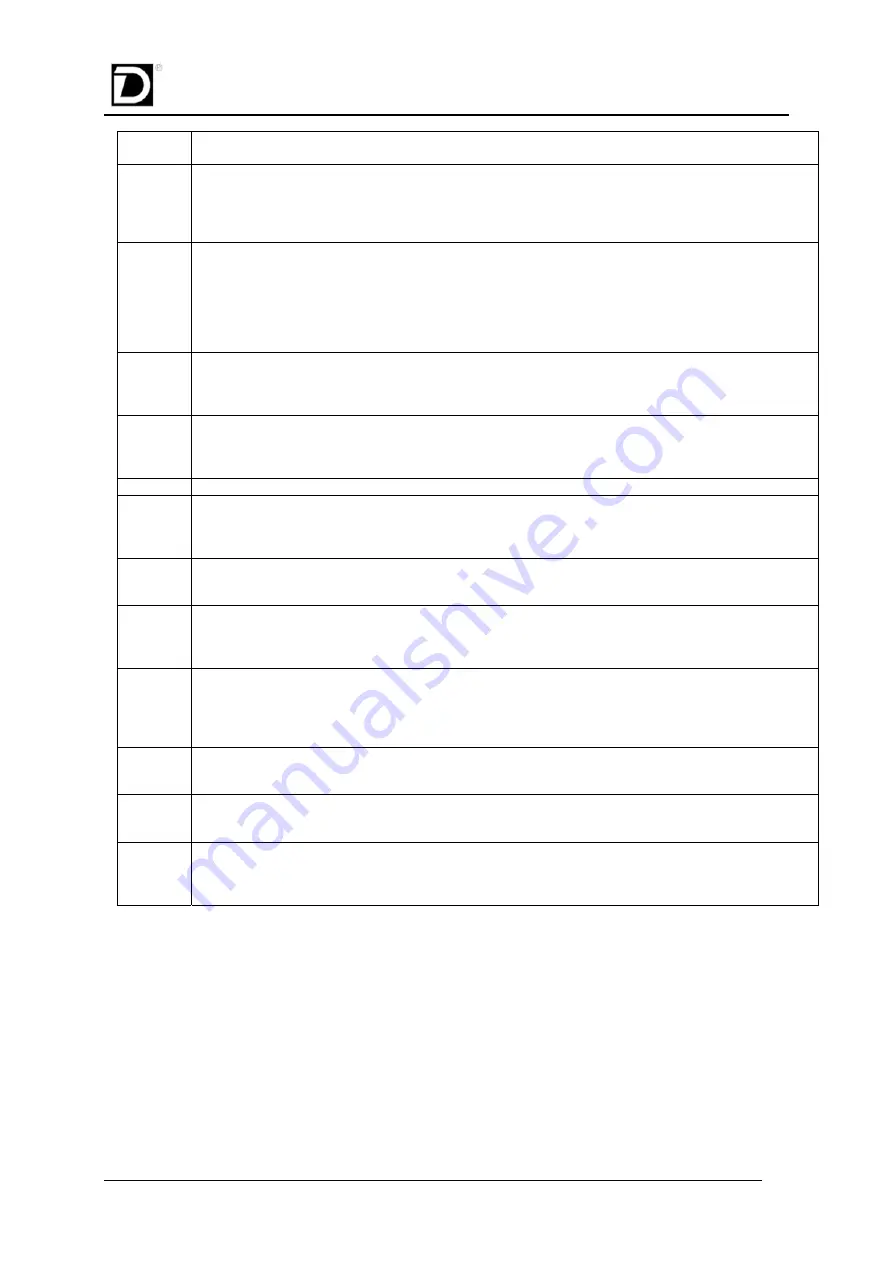

ALARM

CODE

Description

50

The signal of the unlocking switch stays on during the locking phase:

-locking pressure too low (only hydraulic);

-bad position of unlocking switch;

-bad switch connection/wiring (remote application mainly);

-the unlocking switch is defective.

51

The signal of the locking switch stays off during the locking phase:

-locking pressure too low (only hydraulic);

-bad position of locking switch;

-bad switch connection/wiring (remote application mainly);

-wrong control unit code (card for a different size);

-wrong reference cam regulation (turret lock over teeth);

-the locking switch is defective.

52

The signal of the locking switch goes off while the turret is locked:

-problems of pressure (only hydraulic);

-bad switch connection/wiring (remote application mainly);

-the locking switch is defective.

53

The signal of the unlocking switch goes on while the turret is locked:

-problems of pressure (only hydraulic);

-bad switch connection/wiring (remote application mainly);

-the unlocking switch is defective.

55

The two pressure inlet or the LOCKED and UNLOCKED switches are reversed. (only SW rel I)

61

Time-out in fine reference search:

-the zero switch is defective (always off);

-bad switch connection/wiring (remote application mainly);

-the disc cannot rotate.

70

A tool is called before executing the zero cycle:

-error in programming logic of CNC;

-the operator did not call the reference cycle.

71

Parity Error in position code:

-error in programming logic of CNC;

-problems on wiring (PBIT** and PARITY)

-slow outputs of CNC/PLC (the output value van be incorrect when the PSTART signal is given)

72

A tool non existing has been called:

-error in CNC programming;

-turret not correctly configured (check the number of positions set by PTAB01 and PTAB02 signals - LK1 and

LK2 in connection box);

-wiring problems.

73

A variation in position code has been detected but the PSTART signal is not arrived in within 2 seconds:

-error in CNC programming;

-wiring problems (PSTART signal not connected).

74

The time limit of continuos rotation of disc has been reached:

-the turret has been activate in maintenance mode or service for long time;

-the indexing frequency is too high.

78 or 77

The configuration input signals PTAB01 and PTAB02 are not configured (number of positions):

-error in PTAB01 and PTAB02 setting (LK1 and LK2 in connection box);

-the 24 V DC supply is delayed for more than 500 ms in respect of the 230 V AC auxiliary supply (the

configuration has not been loaded correctly).

Note:

the code number is memorised by the control unit and can be read with a Duplomatic

diagnostic software installed on a PC with the RS232 interface.