24

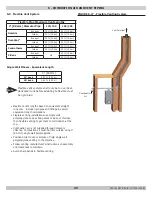

6.5 Approved Venting Materials

6 - COMBUSTION AIR AND VENT PIPING

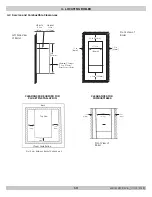

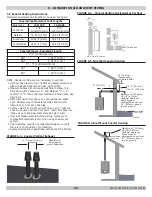

6.6 Vent Termination

•

Terminate combustion air and vent pipes with fittings or

coaxial vent kit.

Use horizontal pipe for vent and 90° elbow for

combustion air termination when using fittings.

• Separate vent terminal from air inlet terminal to prevent

flue gas recirculation. If T-Terminal is used on flue pipe

at sidewall, air inlet terminal shall be at least 36" or more

away from vent terminal.

• Locate combustion air termination as far as possible from

swimming pool, swimming pool pump house, and other

sources of airborne chlorine.

• Locate combustion air and vent terminals as required by

authority having jurisdiction.

Vent Material Options

125 & 150

165 & 205

1

4" / 2" [100 mm / 50 mm] polypropylene coaxial.

1

5"/3" [125mm/80m] polypropylene coaxial.

2

3" [80mm] polypropylene twin pipe.

Shall be polypropylene on BOTH intake and

exhaust.

2

3" [80mm] polypropylene twin pipe.

Shall be polypropylene on BOTH intake and

exhaust.

3

3" [80mm] flexible polypropylene for chimney

exhaust vent, shall have rigid 3" [80mm]

polypropylene on air intake.

3

2" [50mm] polypropylene twin pipe.

Shall be polypropylene on BOTH intake and

exhaust.

4

3" [80mm] Twin pipe CPVC.

PVC optional on intake ONLY.

4

3" [80mm] flexible polypropylene for chimney

exhaust vent, shall have rigid 3" [80mm]

polypropylene on air intake.

5

3" [80mm] Twin pipe CPVC.

PVC optional on intake ONLY.

* Note: Adapters and fittings used with all vent systems shall be from same manufacturer and compatible with the vent

pipe. See list for approved Manufacturers.

Installation shall conform to requirements of authority having

jurisdiction or in absence of such requirements:

• USA - National Fuel Gas Code, ANSI Z223.1/NFPA 54.

• Canada - Natural Gas and Propane Installation Code,

CAN/CSA B149.1

1.

Venting shall be properly supported.

WARNING

Manufacturer recommends this condensing boiler be

vented with approved polypropylene venting material.

Use only materials listed below for vent pipe, intake

air pipe, and fittings. Failure to comply could result in

death or serious injury.

!

WARNING

Do not use cellular core pipe. Only specified sized

pipes are to be used. When using venting material

other than boiler manufacturer's venting, note the

correct installation procedure. Failure to follow these

instructions could result in death, or serious injury.

!

WARNING

•

Covering non-metallic vent pipe and fittings with

thermal insulation shall be prohibited.

•

Use of cellular core PVC for venting flue gas could

result in death, or serious injury.

• Coaxial venting shall be fastened with screws. Dual

flue venting is NOT fastened with screws.

!

2.

Boiler shall not support any type of vent system.

3.

All piping, glue, solvents, cleaners, fittings and

components must conform to ASTM and ANSI standards.

In Canada ULC S636 and in the USA UL 1738 schedule 40

CPVC are the only approved vent system to be used as an

alternative to polypropylene venting for the exhaust pipe

4.

Manufacturer requires use of a spring clamp at every

push-fit gasket connection when using a single wall

polypropylene vent system.

Approved Polypropylene Manufacturers

* Natalini

* DuraVent

®

*Centrotherm

* Z-Flex

®

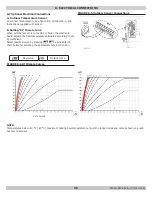

Note: Maximum equivalent length may vary between

manufacturers.

240011947 REV B, [03/31/2018]

Summary of Contents for DCB-125

Page 2: ...DCC 205 ...

Page 4: ...DCB 165 ...

Page 65: ...61 APPENDIX A WIRING DIAGRAMS A 1 MODELS 125 Heat Only 240011947 REV B 03 31 2018 ...

Page 66: ...62 APPENDIX A WIRING DIAGRAMS A 2 MODELS 165 Heat Only 240011947 REV B 03 31 2018 ...

Page 67: ...63 APPENDIX A WIRING DIAGRAMS A 3 MODELS 150 Combi 240011947 REV B 03 31 2018 ...

Page 68: ...64 APPENDIX A WIRING DIAGRAMS A 4 MODELS 205 Combi 240011947 REV B 03 31 2018 ...

Page 69: ...65 NOTES 240011947 REV B 03 31 2018 ...

Page 70: ...66 NOTES 240011947 REV B 03 31 2018 ...

Page 81: ...9 125 WITH ZONE CIRCULATOR PUMPS 125 with Zone Circulator Pumps PN 240011430 REV G 03 31 18 ...

Page 84: ...12 125 WITH ZONE VALVES PIPING DIAGRAM 125 with Zone Valves PN 240011430 REV G 03 31 18 ...

Page 90: ...18 165 with Zone Valves 165 WITH ZONE VALVES PIPING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 94: ...22 150 205 WITH ZONE PUMPS WIRING DIAGRAM 150 205 With Zone Pumps PN 240011430 REV G 03 31 18 ...

Page 102: ...30 MODEL 125 Heat Only 125 HEAT ONLY WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 103: ...31 MODEL 165 Heat Only 165 HEAT ONLY WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 104: ...32 MODEL 150 Combi 150 COMBI WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 105: ...33 MODEL 205 Combi 205 COMBI WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 110: ...38 Low Water Cutoff Detail LOW WATER CUTOFF NO NO YES PN 240011430 REV G 03 31 18 ...

Page 111: ...39 NOTES PN 240011430 REV G 03 31 18 ...

Page 112: ......

Page 115: ......

Page 116: ......