44

9.10 Chimney Sweep Function (CO

2

Adjust)

For correct boiler operation, content of (CO

2

- O

2

) in the combustion flue must be within tolerances indicated in table below.

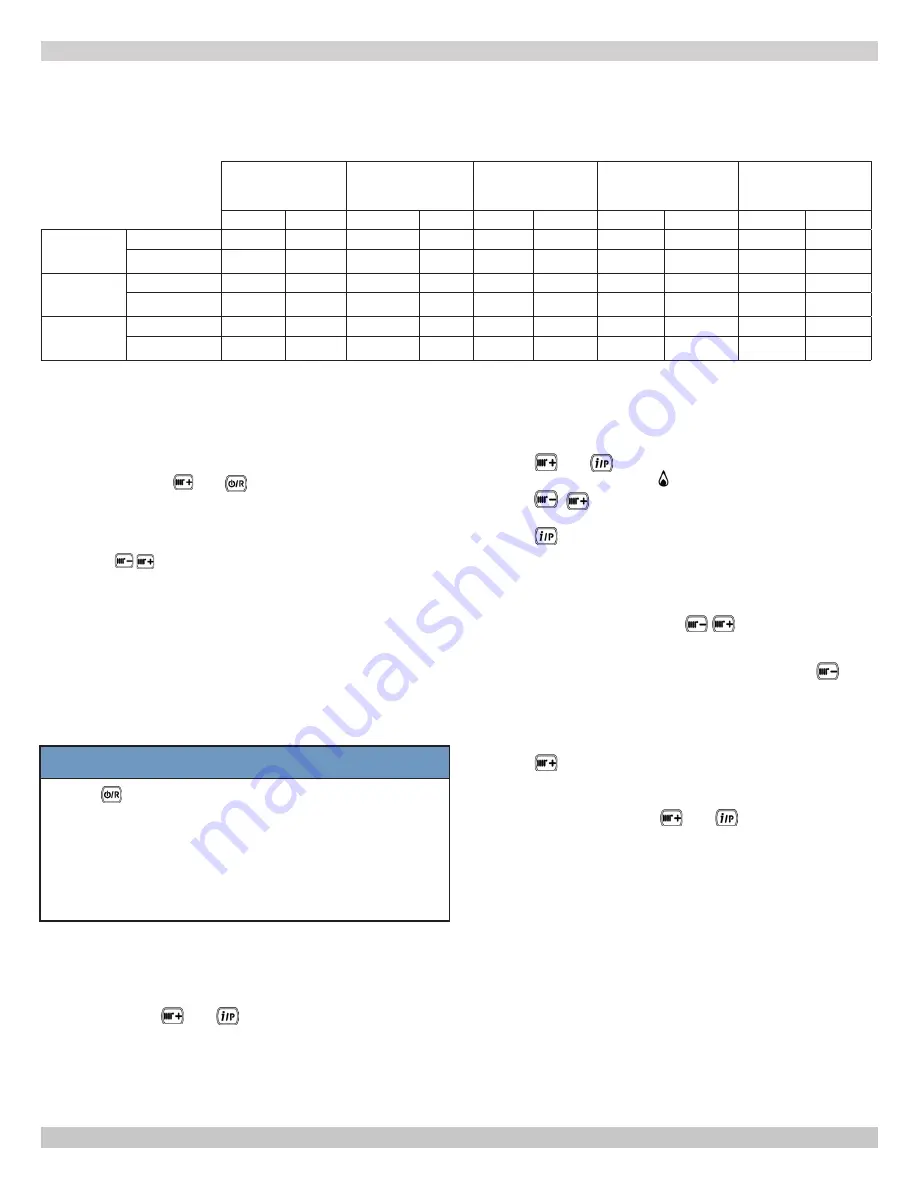

COMBUSTION TABLE

Gas A

(Natural Gas)

DCB-125

Gas A

(Natural Gas)

DCC- 150

Gas A

(Natural Gas)

DCB-165

Gas A

(Natural Gas)

DCC-205

Gas E (LPG)

CO2 %

O2 %

CO2 %

O2 %

CO2 %

O2 %

CO2 %

O2 %

CO2 %

O2 %

Maximum

power (100%)

Nominal value

8.7

5.4

9.0

4.9

9.0

4.9

9.0

4.9

10.0

6.0

Permitted value 8.2 – 9.3 6.3 – 4.3

8.5 – 9.5 5.7 – 4.0 8.7 – 9.3 5.4 – 4.3 8.7 – 9.3

5.4 – 4.3

9.5 – 10.5 6.8 – 5.2

Ignition power

(*)

Nominal value

8.7

5.4

8.7

5.4

8.7

5.4

8.7

5.4

10.8

4.8

Permitted value 8.2 – 9.3 6.3 – 4.3

8.2 – 9.3 6.3 – 4.3 8.2 – 9.3 6.3 – 4.3 8.2 – 9.3

6.3 – 4.3 10.3 – 11.3 5.5 – 4.1

Minimum

power (0%)

Nominal value

8.8

5.2

8.8

5.2

9.0

4.9

9.0

4.9

10.0

6.0

Permitted value 8.2 – 9.3 6.3 – 4.3

8.2 – 9.3 6.3 – 4.3 8.7 – 9.3 5.4 – 4.3 8.7 – 9.3

5.4 – 4.3

9.5 – 10.5 6.8 – 5.2

Chimney Sweep Function enables boiler to generate maximum

heating power.

After activation, boiler power % can be adjusted from

minimum (0%) to maximum (100%) in DHW mode.

A. Press and hold

and

at the same time for 6

seconds. When the function is enabled, displays shows

“

On

” for few seconds followed by program row “

303

”

alternating with % of boiler power.

B. Press

to gradually adjust power (increments of

1%).

C. To exit press both buttons together for at least 6

seconds.

If value of

CO

2

-O

2

is different, check the electrodes and their

relative distances. See Figure 11-1.

If necessary, replace electrodes and position them correctly.

If problem persists, use "

COMBUSTION ADJUSTMENT

FUNCTION (CO

2

%

)". See Section 11 General Maintenance,

Figure 11-1 Electrodes.

NOTICE

• Press

to display instantaneous flow temperature for

15 seconds.

• Use a regularly calibrated combustion analyzer for

combustion analysis.

• During normal operation boiler performs combustion

control cycles. In this phase CO values higher than 400

ppm can occur for brief periods of time.

9 - START UP PROCEDURE

(*)

Automatically calculated from the PCB

9.12 Check Firing Rate

1.

Measure input, if a gas meter is installed in the system.

• Turn off gas to all other appliances.

• Activate some heating zones to dissipate heat.

•

Set boiler on high fire using Chimney Sweep Function.

• Use ½, 1 or 2 cu ft dial on gas meter. Measure time

required for two or more complete revolutions. Measure

time

for one or more minutes.

• Calculate input.

9.11 Combustion Adjustment Function (CO

2

%)

This function sets out to partially adjust the value of CO

2

%.

Use the following procedure:

1.

Press buttons

and

together for at least 6 seconds.

When the function is enabled, displays shows “

On

” for a

few seconds followed by program row “

304

” alternated

with the % of boiler power;

2.

After burner is lit, boiler reverts to maximum DHW power

(100). When display shows "

100

" it is possible to partially

adjust value of CO

2

%;

3.

Press

and

. Display shows "

00

" alternating with

function number "

304

" (

flashes);

4.

Press

to raise or lower the amount of

CO

2

(from -3 to +3);

5.

Press

to save new value. Power value "

100

" will show

on display again. Boiler continues operating at maximum

DHW power.

This procedure can be used to adjust

CO

2

to ignition power

and minimum power by pressing

after performing step

5 above.

6.

After saving the new value (step 5 above), press

to set boiler to ignition power. Wait for value of

CO

2

to stabilize. Adjust as described in step 4 of procedure

(power value is a number <> 100 and <> 0). Repeat step

5 to save.

7.

Press

to adjust boiler to

minimum power

. Wait for

value of

CO

2

to stabilize. Go to step 4 to adjust (power

value = 00);

8.

Exit function by pressing

and

together for at least

6 seconds, see step 1.

240011947 REV B, [03/31/2018]

Summary of Contents for DCB-125

Page 2: ...DCC 205 ...

Page 4: ...DCB 165 ...

Page 65: ...61 APPENDIX A WIRING DIAGRAMS A 1 MODELS 125 Heat Only 240011947 REV B 03 31 2018 ...

Page 66: ...62 APPENDIX A WIRING DIAGRAMS A 2 MODELS 165 Heat Only 240011947 REV B 03 31 2018 ...

Page 67: ...63 APPENDIX A WIRING DIAGRAMS A 3 MODELS 150 Combi 240011947 REV B 03 31 2018 ...

Page 68: ...64 APPENDIX A WIRING DIAGRAMS A 4 MODELS 205 Combi 240011947 REV B 03 31 2018 ...

Page 69: ...65 NOTES 240011947 REV B 03 31 2018 ...

Page 70: ...66 NOTES 240011947 REV B 03 31 2018 ...

Page 81: ...9 125 WITH ZONE CIRCULATOR PUMPS 125 with Zone Circulator Pumps PN 240011430 REV G 03 31 18 ...

Page 84: ...12 125 WITH ZONE VALVES PIPING DIAGRAM 125 with Zone Valves PN 240011430 REV G 03 31 18 ...

Page 90: ...18 165 with Zone Valves 165 WITH ZONE VALVES PIPING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 94: ...22 150 205 WITH ZONE PUMPS WIRING DIAGRAM 150 205 With Zone Pumps PN 240011430 REV G 03 31 18 ...

Page 102: ...30 MODEL 125 Heat Only 125 HEAT ONLY WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 103: ...31 MODEL 165 Heat Only 165 HEAT ONLY WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 104: ...32 MODEL 150 Combi 150 COMBI WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 105: ...33 MODEL 205 Combi 205 COMBI WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 110: ...38 Low Water Cutoff Detail LOW WATER CUTOFF NO NO YES PN 240011430 REV G 03 31 18 ...

Page 111: ...39 NOTES PN 240011430 REV G 03 31 18 ...

Page 112: ......

Page 115: ......

Page 116: ......