8

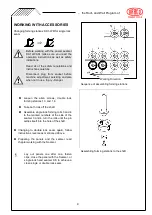

WORKING CONSEQUENCE CLOSING THE SEAM

Dual safety switch K9-1-DF assembled to the seamer,

check the position of pin first before switching the

seamer to “on “.

If pin is in position 1 the machine will not switch

off automatically!

Pin in position 2 the dual safety switch is in operation.

Press locking handle down all the way, to

ensure that the handle does not open up

again.

Secure a safety rope to the lifting eyes.

Before working with the dual safety switch, check the

function of the switch.

Working direction variable up or down.

◼

Seamer must be operated on a grounded socket

only.

◼

To operate seamer switch to

”I” and push knob

2 (see page 20)

◼

After switching the machine to on position the

power seamer will work automatically and close

the panel to a double lock seam.

◼

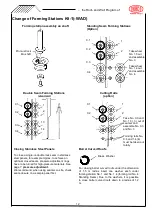

Insert the seamer, locking handle open, with the four

forming rolls into the panel.

◼

The first two forming rolls No. 1 and No. 2 must be set

under the single lock seam. See picture.

◼

At the end of the ridge or eave switch machine

to “0” off.

◼

Open locking handle.

◼

Take seamer out of the panel.

Insert the rolls no. 1 and no. 2 at the beginning of the seam

If there is an obstruction, the rest of the panel has to

be closed with the single lock hand seamer K8 and

double lock seamer K7.

The locking handle must be positioned to the

forming side

If there is an obstruction, windows, chimneys,

vent pipes, move locking handle against the

spring and to the top. See picture previous

page.

Take seamer out of the panel, move locking

handle down, spring pushes pin into the

bracket, move handle to the top and take

seamer off.

Lock handle

... the Roof- and Wall Program of

0.1

0.2

0.3

0.4

1

2

1.3

1.4