10

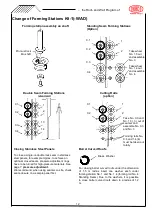

Cutting Rolls K9-1-AR

To prevent waste jam in the seamer, no forming

stations to station 1.4 or 0.4. The machine works only

with 4 driving rolls and 2 cutting rolls.

Please read the operation instructions as

well es safety indications before working

with the power seamer K9-1(-WAD).

Read all the safety regulations and

instructions carefully. All instructions

have to be followed.

Changing seamer for seam cutting

Loosen the screws on the following forming

stations. See chart.

Rolls to be used

Changing to double or single lock, follow instructions

reverse as mentioned above. See chart.

Double lock 1 2

1.3

1.4

Single lock 1 2

3

4

⚫

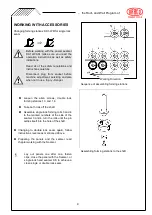

Working Sequence Cutting Double Lock- or

Single Lock Seam

Forming stations diagram

Seam cutting, a burr could be on both sides

of the panel.

Injury - Wear gloves

Working direction variable up or down or

opposite.

Open locking handle all the way.

Set seamer, with the first two rubber drive wheels into

the panel.

Cutting rolls must be stationed just before cutting the

seam if there is an obstruction, cut seam about 20 cm

by hand set machi

ne in and switch machine to “on“

◼

Take the rolls position 3/1.3, 4/1.4 and 0.3

0.4 off the shaft

◼

Assemble cutting rolls 3 and 0.3 to the

marked numbers at the side of the seamer

3 and 0.3.

◼

Turn both rolls until the pin settles itself into

the hole of the shaft.

The locking handle must be set to the side of

the seam.

◼

Fasten cutting rolls with screws again.

... the Roof- and Wall Program of

Cutting rolls

3

0,3