Installation, Operation and Maintenance Manual

Unimaster Dust Collectors – Series UMA 40-750

42

SPECIFICATION

Explosion relief

Most carbonaceous dusts, plastics, fertilisers, pharmaceuticals, fossil fuels,

chemicals, foodstuffs and certain metallic dusts present an explosion hazard for

which explosion relief panels must be fitted. Expert advice must be sought from

Health and Safety authorities where dust is thought to be explosive and toxic.

For applications where the dust collector is to be installed in a potentially

explosive atmosphere, the electrical specification will be upgraded to

suit. e.g. EEx motors, cabling and terminal box.

The classification of the hazard (Zone) must be specified when ordering

the collector to ensure that it is to the correct specification.

Details on the explosion relief assembly can be found in Publication

2713.

Details of the controller can be found in Publication IOM AK0303001.

Acoustic diffuser

UMA 40 and 40MM collectors can be fitted with an acoustic diffuser to reduce

noise levels. (UMA 70 to 750 collectors have acoustic diffusers fitted as standard).

The acoustic diffuser for UMA 40 and 40MM collectors is mounted at the rear (or

side if the collector has explosion relief).

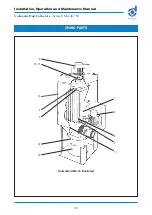

Secondary or absolute filter (not available on UMA 40 or 70 collectors)

A secondary filter (see fig. 16) can be fitted to Unimasters handling hazardous

dusts, enabling filtered air to be recirculated safely back into the working area. It

also acts as a fail-safe device should the main filter element become damaged.

For special applications, absolute (HEPA) filters are available (details on request).

With certain dusts the filtered air must not be recirculated – if in doubt refer to

Donaldson or the appropriate Health and Safety authorities. Each secondary filter

panel is inserted through the front access door of its housing and sealed tightly

Figure 16 Secondary filter assembly (UMA 450 illustrated)