Torit Backward Inclined Fan, TBI-3 through 30

14

Problem

Probable Cause

Remedy

Excessive vibration

Externally transmitted vibration

Isolate collector from external vibration.

Accumulation of foreign

material on the wheel

Clean the wheel.

Excessive system pressure or

restriction of airflow due to

closed dampers

Open dampers far enough for fan to operate in stable

flow regime.

Inadequate performance

Fan running too slowly

Check power frequency against fan motor design

frequency.

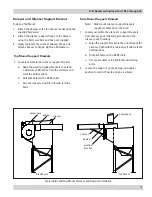

Fan wheel rotating in wrong

direction or installed backwards

on shaft

Proper fan rotation is clockwise from the top of the

fan. The fan can be viewed through the back of the

motor.

Poor system design, closed

dampers, air leaks or clogged

filters

Check system for damper positions leak points.

Check filter Delta P.

Sharp deflection of airstream at

fan outlet

Do not place fan discharge next to a wall.

Missing discharge fittings

Install discharge fittings.

Excessive noise

Fan operating near “stall” due

to incorrect system design or

installation

Correct system or replace with correctly sized fan.

Vibration originating elsewhere

in the system

Vibration isolate collector from the system.

Loose accessories or

components

Tighten accessories or components.