11

Donaldson Company, Inc.

Donaldson Torit TBI fans are manufactured to high

standards with quality materials and components. Proper

maintenance will ensure a long and trouble-free service

life.

Regular fan maintenance should

include the following:

Check the fan wheel for any wear or corrosion,

as either can cause catastrophic failures.

Check also for the build-up of material which

could cause unbalance resulting in vibration,

bearing wear and serious safety hazards. Clean

or replace the wheel as required.

Lubricate the bearings, but do not over

lubricate.

Periodically inspect the shaft for dirt buildup,

corrosion and signs of excess stress or fatigue.

During any routine maintenance, all setscrews

and bolts should be checked for tightness. See

Torque Value Table.

The key to good fan maintenance is regular and

systematic inspection of all fan parts. Inspection

frequency is determined by the severity of the application

and local conditions. Strict adherence to an inspection

schedule is essential.

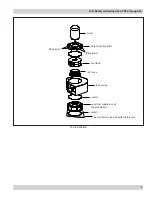

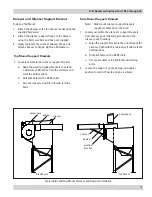

When installing a new wheel or cone, the

proper wheel-to-drive side plate must be

maintained as shown in Side Plate Clearance

Table. Inlet cone clearance should be uniform

around the circumference.

Maintenance Information

Instruct all personnel on safe use and maintenance

procedures.

Use proper equipment and adopt

all safety precautions needed

for servicing equipment.

Electrical service or maintenance work must

be performed by a qualified electrician and

comply with all applicable national and local

codes.

Turn power off and lock out electrical

power sources before performing service or

maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

When mounting fan in an

outdoor or high humidity

environment, mount the motor with drain holes

facing down to extend motor life.

For additional information, contact the motor

manufacturer.

A

Wheel to Drive Side Plate Clearances

inlet cone

clearance