5

Donaldson Company, Inc.

Torque Values for TBI

Setscrew Size

Diameter

Carbon Steel Setscrew

Torque*

In.

TBI 3-10

Lb. - Ft.

TBI 15-30

Lb. - Ft.

1/4

6.2

6.2

5/16

12

12

3/8

21

22

7/16

33

30

1/2

50

55

5/8

97

100

3/4

168

150

7/8

267

165

1

400

250

*Stainless steel setscrews are not hardened and should not

be tightened to more than half of the values shown.

Set screws should never be used more than once. If the

set screws are loose, they must be replaced. Use only

knurled, cup-point screws with a nylon locking patch.

Do not allow the fan wheel to

come loose from the motor as it

may cause severe injury or property damage.

To ensure proper attachment of the fan wheel:

Tighten all setscrews in fan wheel.

Repeat after 8 hours of operation.

Repeat again after two weeks of operation.

Reference Torque Value Table.

For additional information, contact the motor

manufacturer.

TBI fans are dynamically balanced and tested at

operating speeds to check for conformance to vibration

limits. All fans must be adequately supported for smooth

operation.

Safe operating spped is a function of system temperature

and wheel design. TBI fans should not be operated

above 3,600 RPM.

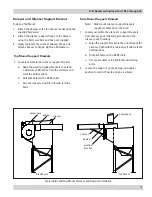

Fan Installation

Electrical installation, service,

or maintenance work must

be performed by a qualified electrician and

comply with all applicable national and local

codes.

Turn power off and lock out all power before

performing service or maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

Mounting a fan blower on the side of a

collector requires a side power adapter to

support the weight of the fan blower.

Poorly installed fan blowers may separate from

the collector resulting in personal injury and/or

property damage.

When mounting fan in an outdoor

or high humidity environment,

mount the motor with drain holes facing down

to extend motor life.