13

5

COMMISSIONING OF THE BOILER

5.1

Prior warnings

Repair and maintenance of the boiler must be carried out by a qualified professional, authorised by

DOMUSA TEKNIK

. For optimum functioning and conservation of the boiler, it should be serviced

annually.

Carefully read this instruction manual and keep it in a safe, easily-accessible place.

DOMUSA

TEKNIK

will not be liable for any damages caused by failure to follow these instructions.

Before any servicing,

disconnect the boiler from the mains

.

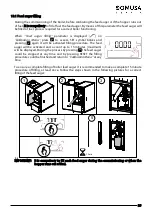

5.2

Electrical Connection

Both boilers should have independent electrical power connections. Special attention must be paid

to the maximum consumption of the two-boiler assembly (2875 W) in the event that they are both

powered from the same socket, as it must be able to support such use.

Both boilers are equipped for connection to 230 V ~ 50 Hz.

The socket should have an

appropriate earth connection.

5.3

Filling the installation

The hydraulic installation must include a fill valve, drain valves and the necessary hydraulic

components for correctly filling the installation.

To fill the installation, open the fill valve until the parameter

“Water pressure”

of

“User Menu”

shows

a pressure of 1 - 1.5 bars. The installation must be filled slowly, bleeding the air from the water

circuit using the drain valves provided on the same. Close the fill valve after filling.

BioClass HM

boiler has a pressure sensor for controlling the pressure of the installation. If the

installation does not have the minimum pressure set at

P.19

parameter of

”Technical Menu”

(by

default 0.5 bar), a low pressure alarm will appear ("

E-19

").

IMPORTANT: Switching on the boiler with no water inside could result in serious damage.

5.4

Initial calibration of the feed auger

BioClass HC

boiler is equipped with a feed auger to supply the fuel. Follow the instructions

described in

"Installing the hopper”

section

to install it correctly. Due to diversity of feed augers and

the range of different hoppers, it is needed to calibrate the feed auger minimum twice to assure the

correct running.

During the commissioning, after filling the installation, ("

E-25

") alarm code is displayed. It isn’t

possible to switch on the boiler before calibrating the feed auger. Follow the instructions described

in “

Feed auger calibration”

section of

“Setup menu”

to assure a correct calibration. Once the

calibration is finished, "

E-25

") alarm would disappear and it will be possible to switch on the boiler.