BioClass HC

12

4.7

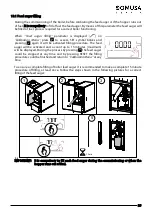

Combustion product removal

The

BioClass HC

boiler is an assembly of two

BioClass HM

boilers and it is essential that each boiler

is connected to a flue, i.e. a smoke duct able to create a pressure drop (which in this case should be

between 0.10 and 0.20 mbar), in compliance with the applicable laws to this regard.

The combustion product exhaustion ducts must be installed by qualified personnel and must

comply with the regulations in force. For the flue to create a pressure drop, the following

recommendations should be taken into account:

- It should be suitably insulated.

- It should be vertical, avoiding any angles greater than 45º.

- It should always have the same diameter. It is recommendable for it to be circular, and never

any narrower than the boiler outlet.

-

It is obligatory to install a fume inspection plate with condensation collection, to remove

the condensation generated in the flue.

Otherwise, the condensation may reach the inside of

the boiler and cause irreparable damage,

which would not be covered by DOMUSA TEKNIK’s

guarantee

.

The condensation pipe should lead to a drain outlet

, as a large amount of water

may be generated. This connection must be made in compliance with the regulations for

draining off condensation water to the drain network.

-

It is recommended to install a draught stabiliser

to prevent any pressure drop variations in

the flue due to atmospheric conditions, which could affect correct boiler combustion.

This

draught stabiliser must be installed below the fume inspection plate to prevent any

leakage of combustion gases.

- It is recommended to connect each boiler to an independent chimney to avoid possible

revokes.