19

- Unscrew securing screw of boiler-insulation.

(Figure 68)

- Turn metal casing of boiler-insulation so that the joint rim becomes visible.

- While slightly pressing the metal casing of the boiler-insulation, detach the

rims.

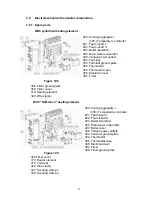

(Figure 69)

- Turn out insulation – metal casing and rock wool together – from under the

boiler.

(Figure 70)

- Loosen screw securing the element, pull out heating element upwards. If

the heating element is jammed in the heating tube, then push it out from

below with a screwdriver.

(Figure 71,72,73)

- Installing the new heating element is done in reverse order. The

heating element must be securely fixed.

-

Attention !

The capacity of a heating element with ”fuzzy logic” control is

different from those with electromechanical control!

- The boiler-insulation can be reinserted by turning it in. The rims must be

snapped together by slightly pressing the metal casing.

- Turn in boiler-insulation so that the securing bore is in the correct position.

- Attach boiler-insulation to back panel with securing screw.

- Adjust

wires.

- Connect electrical connections at the appropriate points.

- Snap it back into printed circuit board. When replacing, make sure that the

driving shaft jointing fits in the potentiometer’s bore.

- Secure wire clamp.

- Reinsert electrical cover, secure with screws.

- Place refrigerator in upright position. Check that that thermostat switch

turns freely in the entire control range.

- Check electrical insulation resistance (with 1000-V electrical insulation

resistance metering device.)

The insulation resistance R

INS

> 2Mohm

Other composition: see section 3

Figure 68

Figure 69

Figure 70

Figure 71

Figure 72

Figure 73