35

BH 5910 / 200217 / 190A

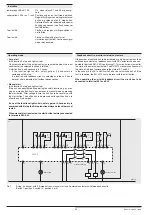

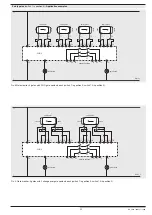

2-Hand control and E-stop

(switch 1 in position 6)

2 pairs of 2-hand buttons can be connected in this function together with

1 e-stop loop. The number of connected button pairs has to be selected

on the device.

K1 and K2 can only be activated, if 4 conditions are fulfilled:

- First all button pairs have to be in initial position.

- The e-stop contacts must be closed and manual start must be activated.

- Both buttons of 1 pair have to be pressed within 0.5 sec.

- All connected pairs have to be operated within 15 sec.

If changeover contacts are used in the 2-hand buttons the switchover time

has to be less then 50 ms. If it is longer the outputs K1 and K2 are switched

off and the unit gives failure code 7. This failure is stored and can only be

reset by disconnecting the auxiliary supply.

After e-stop or power failure the start button must always be activated.

The e-stop loop must be closed and all 2-hand button pairs must be in

initial position.

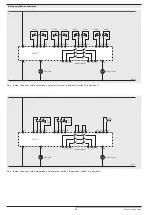

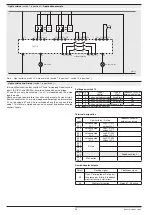

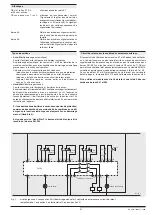

2-hand control and e-stop,

with 2 pairs of buttons with 2 NO contacts each and 1 e-stop loop

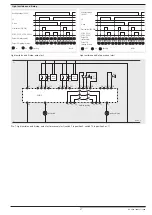

Function diagram

Button 2 S2 (S23/S24)

Auxiliary voltage

(A1/A2)

Button 1 S1 (S11/S12)

Button 1 S2 (S13/S14)

Button 2 S1 (S21/S22)

E-stop

Start button (S43/S44)

K1/K2

(13-14, 23-24, 33-34)

48 (no button activated)

58 (all buttons activated)

: off

: on

: flashing

M8447

Set-up instructions

The device has to be connected as shown in the application examples. When

connecting the push-buttons in parallel or in series the safe function of the

relay is disabled. The buttons must be designed and installed in a way, that

it is not possible to manipulate or to operate them without intention.

The distance between push buttons and dangerous area must be chosen

in a way that it is not possible to reach the dangerous area after release of

one button before the dangerous movement comes to standstill.

The safety distance "S" is calculated with the following formula:

S = V x T + C

a) moving speed of person V = 1 600 mm/s

b) stopping time of the machine T (s)

c) Additional safety distance C = 250 mm

If the risc of accessing the dangerous area is prohibited while the push

buttons are pressed e.g. by covering the buttons, C can be 0. The minimum

distance has to be in this case 100 mm. See also EN 574.

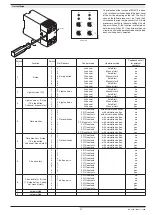

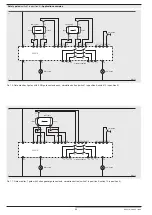

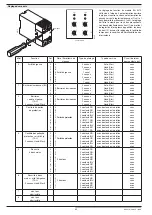

Settings on switch 10

Switch

10

Number of

button pairs

Type of

button contacts

Feedback circuit for

external contactors

0

1

2 NO contacts

no

1

2

2 NO contacts

no

2

1

2 C/O contacts

no

3

1

2 NO contacts

yes

4

2

2 NO contacts

yes

5

1

2 C/O contacts

yes

6-9

position not allowed (failure 5)

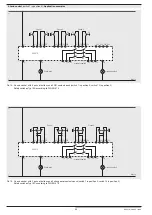

Terminal designation

Ter-

minal

Pair of buttons with

2 NO contacts each

Pair of buttons with

2 C/O contacts each

Feedback circuit for

external contactors

S11

S12

Pair 1, button S1

button S1,

NO contact

button S1,

common connector

S14

S13

Pair 1, button S2

button S1,

common connector

button S1,

NC contact

S21

S22

Pair 2, button S1

button S2,

NC contact

button S2,

common connector

S24

S23

Pair 2, button S2

button S2,

common connector

button S2,

NO contact

1 E-stop loop and 1 Start button

S31

S32

E-stop, channel 1

S34

S33

E-stop, channel 2

S41

S42

not connected

Feedback circuit

S44

S43

Start button

Semiconductor outputs

Output

Flashing signal

Continuous signal

48

E-stop loop open or starting

conditions not fulfilled or failure

in feedback circuit or on acknow-

ledge button/start button.

All buttons in initial

position. For a new start

all

buttons have to be

linked according to

the starting conditions.

58

Press acknowledge button.

All buttons are

activated,

K1, K2 are energized.