Operation

68

Manual

DLoG X Series

8.2.5.

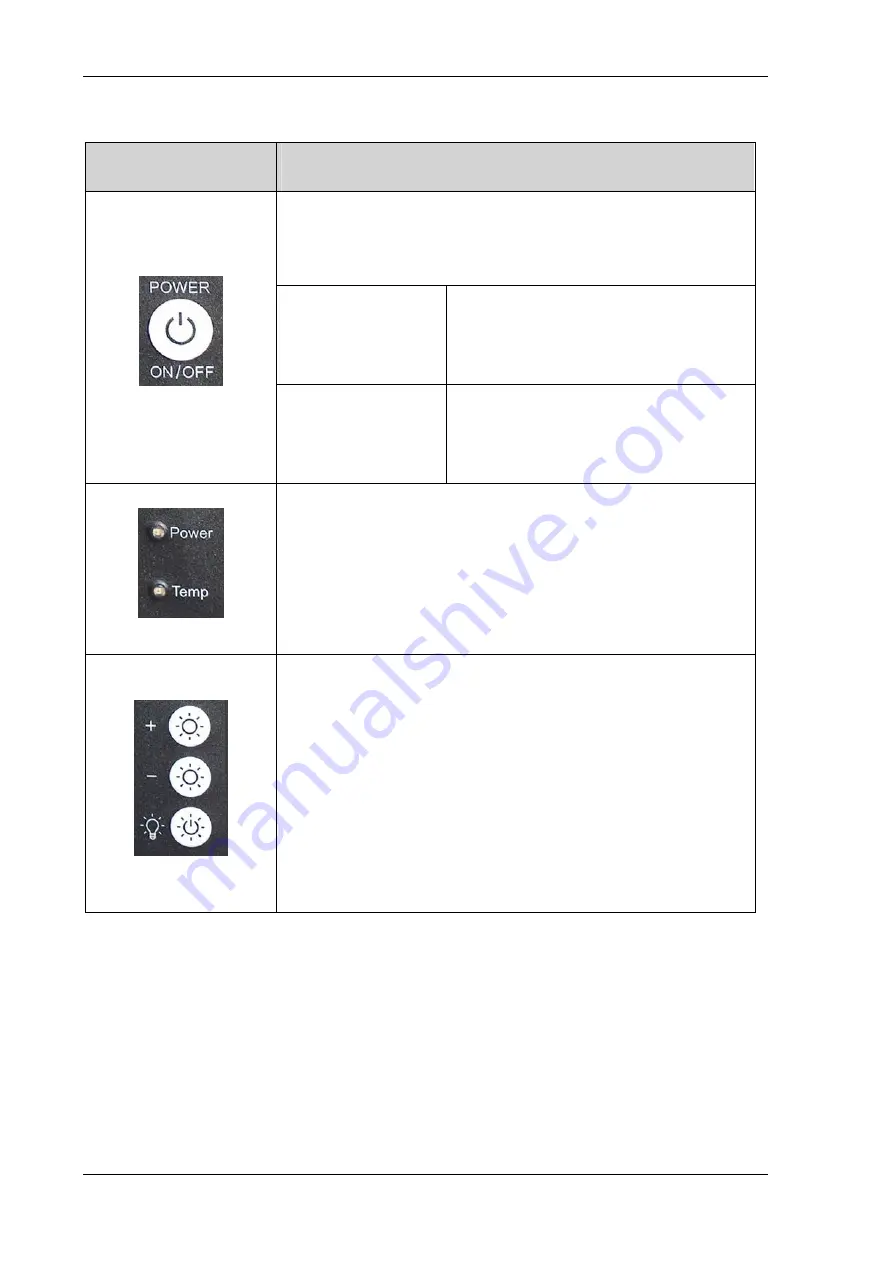

Front controls (standard)

Indicator/control

Explanation

<Power> button to switch the DLoG X 7 on/off:

This button has been preconfigured by DLoG to provide the

following functions by default:

DLoG X 7

with automatic

switch-off

<Power> button is

not

used for powering up

the unit. If the button is pressed before the

shutdown delay time has elapsed, the unit

is powered down immediately.

DLoG X 7

without

automatic

switch-off

<Power> button is used to power up the

unit. If the button is pressed while the unit is

operating, this results in a HARD shutdown.

This may lead to data loss!

Power

(green LED): indicates connection to a power supply

Temp

(red LED) indicates an excessively high or low

temperature inside the unit

<+> button for manual brightness control

<-> button for manual brightness control

Switching the backlight on/off or toggling between manual

and automatic brightness control

Summary of Contents for DLoG X 10

Page 1: ...3 10 DLoG X 7 DLoG X 10 DLoG X 12 Manual ...

Page 3: ......

Page 12: ......

Page 55: ...Initial operation DLoG X Series Manual 43 COM2 Options 13 Audio Option ...

Page 87: ...Boot loader DLoG X Series Manual 75 Figure 9 2 Boot loader diagram 2 ...

Page 109: ...Audio Option DLoG X Series Manual 97 Figure 13 2 Audio port circuit diagram ...