16 / 20

Wireless Installation

When connected to a Wireless Receiver, controllers can receive input signals from a wide selection of wireless devices. Compatible wireless devices in-

clude temperature sensors, duct sensors, window/door contacts and light switches. These devices are easy to install, and can be mounted on a wide

range of building materials.

Before connecting any wireless equipment to the controller, refer to the Open-to-Wireless Application Guide.

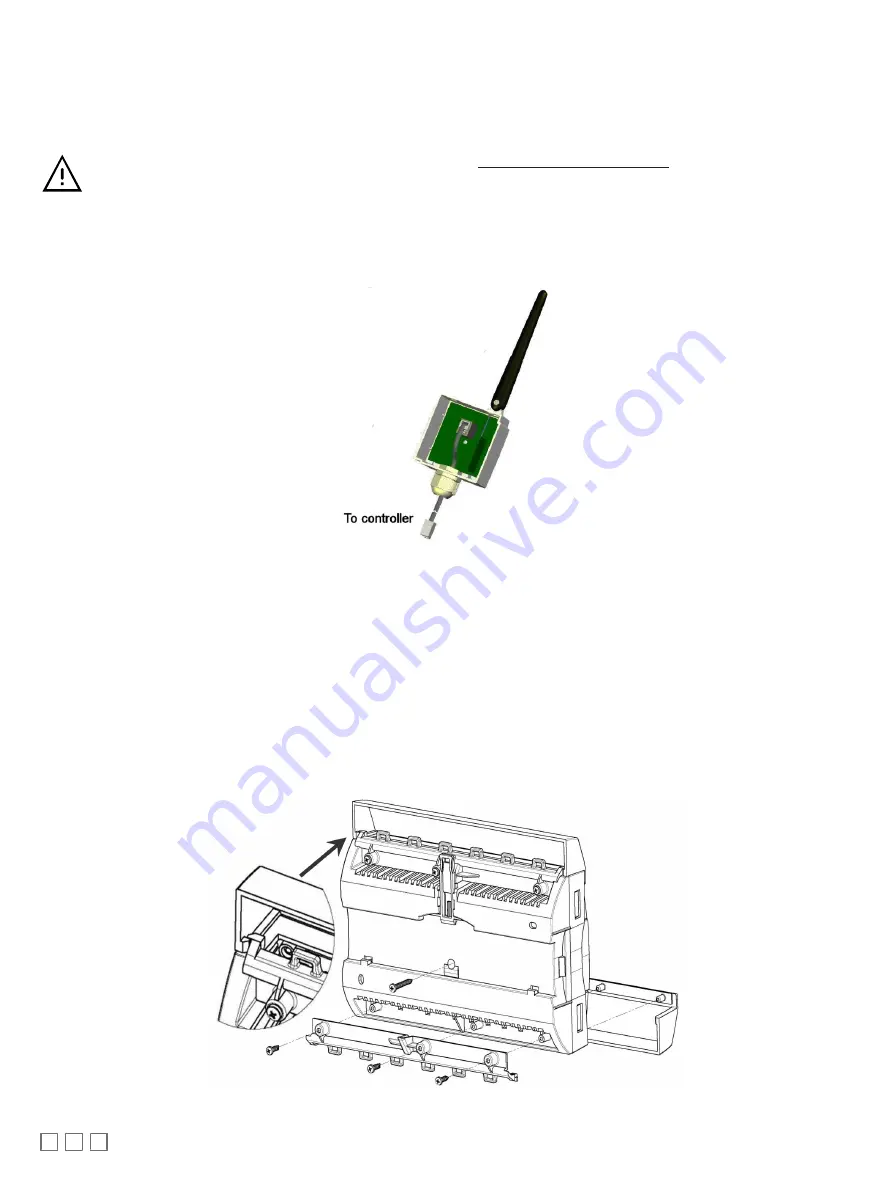

Connecting the Wireless Receiver

The Wireless Receiver is connected to the controller using a 2m (6.5ft) telephone cable with 4P4C modular connectors at both ends. Do not exceed this

cable length. The Wireless Receiver’s telephone socket is located inside the device. To locate it, open the Wireless Receiver by separating its front and

back plates.

Figure 14: Location of the Wireless Receiver’s telephone socket

Connecting to the Controller’s Wireless Port

Each controller has a wireless port in which one end of the Wireless Receiver’s telephone cable plugs in.

Strain relief and Terminal Block Cover

In certain jurisdictions, terminal block covers are required to meet local safety regulations. Strain reliefs and terminal block covers are available for con-

trollers housed in large enclosures and are used to relieve tension on the wiring and conceal the controllers’ wire terminals. Strain reliefs and terminal

block covers are optional and are sold as peripherals.

Prior to connecting all wires, it is recommended to install the strain relief. Three screws are provided for its installation under the bottom part of the enclo-

sure. Tie wraps can then be used to group wires together and attach them securely to the strain relief in an effort to relieve undue tension. If necessary,

the terminal block cover can then be clipped on to the strain relief as shown below.

Figure 15: Large enclosure strain relief and terminal block cover installation