Dingo K9-4 Operation & Maintenance Manual

16

Dingo K9-4 Operation & Maintenance Manual

17

Battery

Always keep the battery clean and fully charged.

Use a paper towel to clean the battery case. If the

battery terminals are corroded, clean them with a

solution of 4 parts water and 1 part baking soda.

Apply a light coating of grease to the battery

terminals to reduce corrosion.

Voltage: 12v, 380 Cold Cranking Amps.

Changing the Hydraulic Fluid

Change the hydraulic fluid after every 500 oper-

ating hours.

HYDRAULICS FLUID SERVICE SHOULD

ONLY BE CARRIED OUT BY YOUR DIN-

GO SERVICE TECHNICIAN IN A CLEAN

ENVIRONMENT.

IMPORTANT:

Do not substitute with auto-

motive oil or severe hydraulic damage may

result.

1

Position the Dingo on a level surface, lower

the arms and turn the ignition key to OFF to stop

the engine. Remove the key.

2

Place large drain pan under the machine that

can hold at least 90 litres.

3

Remove the drain plug from the bottom of the

hydraulic tank and allow the fluid to completely

drain out.

4

Remove the tank tops (Motor MUST be re-

moved) and wipe out the inside of the tank. If

anything unusual is found, consult your Dingo

service centre or a hydraulic expert.

5

Install the drain plug.

6

Fill the hydraulic tank with approximately 90

litres of

HVI 68

hydraulic oil.

7.

Check fluid level in hydraulic tank and add oil

to raise level to 75mm below the top of the tank.

DO NOT OVER FILL.

Note:

Dispose of used oil in accordance with

local authority regulations. Only use

HVI 68

oil. Use of other oil grades can cause loss of

hydraulic power, or damage to machine.

Check Hydraulic Lines

After every 100 operating hours, check hydraulic

lines and hoses for leaks, loose fittings, kinked

lines, loose mounting supports, wear, weather

and chemical deterioration. Replace all mov-

ing hydraulic hoses every 1500 or two years,

whichever comes first. Make necessary repairs

before operating.

WARNING!

Hydraulic pressure escaping

under pressure can penetrate the skin and

cause injury.

Keep hands and body away from pin hole leaks

or nozzles that eject high pressure hydraulic

fluid. A small leak can be dangerous. To find

hydraulic leaks use cardboard or paper.

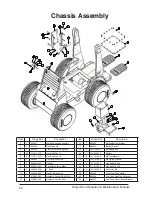

Item

Qty Part Number

Description

1

1 .

Oil Filter Housing

2

1 .

4 x 1/8 O-Ring

3

1 .

3 27/32 x 1/8 O-Ring

4

1 .

3 3/16 x 7/64 O-Ring

5

1 .

Housing Cap

6

1 .

Filter Pot

7

1 .

1 1/4 x 1/8 O-Ring

8

1 .

Filter Spring

9

1 .

Filter Element

10

3 111-211-020

Hex Bolt M6x20

To Replace Hydraulic Filter(Intank).

Clean the front tank top and grille to ensure

there is no debris that can fall onto the tank.

Loosen the 3 bolts on top. The cap is under

spring pressure. Push down on the cap

and remove the 3 bolts. Slowly release the

pressure on the cap and remove. Pull filter

out. Pull black plastic housing out and clean.

Refit housing and refit filter element. Replace

centre cap ensuring O-ring is seated correctly.

Tighten bolts. Clean any spilt oil.

Summary of Contents for K9-4

Page 24: ...Dingo K9 4 Operation Maintenance Manual 24 Main Control Bank Assembly ...

Page 26: ...Dingo K9 4 Operation Maintenance Manual 26 Remote Control Bank Assembly ...

Page 32: ...Dingo K9 4 Operation Maintenance Manual 32 Yanmar Dash Assembly ...

Page 34: ...Dingo K9 4 Operation Maintenance Manual 34 Perkins Dash Assembly ...

Page 38: ...Dingo K9 4 Operation Maintenance Manual 38 K9 4 Arm Assembly ...

Page 43: ...Dingo K9 4 Operation Maintenance Manual 43 Yanmar Engine Assembly Series I ...

Page 49: ...Dingo K9 4 Operation Maintenance Manual 49 K9 4 Perkins Engine Diagram And Part List ...