Dingo K9-4 Operation & Maintenance Manual

10

Dingo K9-4 Operation & Maintenance Manual

11

To turn, decrease pressure on the drive control

lever closest to the direction you want to turn.

The farther you move the drive control levers

in either direction, the faster the machine will

move in that direction.

To slow or stop, move or release the drive control

levers into neutral. (If released the control levers

will automatically return to neutral).

Attachment Tilt Lever

To tilt/crowd attachment forward, slowly push

the tilt lever forward.

To tilt attachment backward, slowly pull the tilt

lever backward.

Loader Arms Lever

To lower Dingo arms, slowly push arm lever

forward.

To raise Dingo arms, slowly pull arms lever

backward.

Control Panel Diagram

1

Drive control levers

2

Attachment tilt lever

3

Loader arms lever

4

Auxiliary hydraulic lever

5

Pump selector valve

6

Throttle

7

Ignition

8

4 in 1 Bucket Lever

9

Flow Divider

10

Hydraulic Immobiliser

11

Warning Light

12

Auxiliary Power Socket

Auxiliary Hydraulic lever

The auxiliary hydraulics lever allows you to alter

the direction of rotation of hydraulically driven

attachments or stop them completely.

ATTENTION:

Ensure auxiliary hydraulic lever

is in neutral position before starting engine.

Aside from starting difficulties the attachment

may move during starting.

To operate attachment in forward direction,

slowly pull auxiliary lever rearward. To operate

attachment in reverse direction, slowly push

auxiliary lever forward.

Pump Selector Lever

When faster ground speed and lifting speed is

required (bucket work) more than attachment

speed and power, push the pump selector lever

to the rearward position (Hare).

When faster attachment speed and power is re-

quired (trenching, post hole digging etc) more

than ground speed and lifting power, push the

pump selector lever to the forward position

(Turtle).

Flow Divider Control

In its normal operating position no flow division

is taking place. Moving the lever forward diverts

oil flow to the attachment and less is available

to the Dingo wheels and arms. This allows

for greater concentration of power where it is

needed most.

The flow divider is mainly used for trenching,

rotary hoeing and stump grinding where it is

important for the attachment to have as much

power as possible and ground speed is not

important.

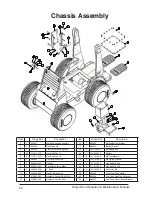

Summary of Contents for K9-4

Page 24: ...Dingo K9 4 Operation Maintenance Manual 24 Main Control Bank Assembly ...

Page 26: ...Dingo K9 4 Operation Maintenance Manual 26 Remote Control Bank Assembly ...

Page 32: ...Dingo K9 4 Operation Maintenance Manual 32 Yanmar Dash Assembly ...

Page 34: ...Dingo K9 4 Operation Maintenance Manual 34 Perkins Dash Assembly ...

Page 38: ...Dingo K9 4 Operation Maintenance Manual 38 K9 4 Arm Assembly ...

Page 43: ...Dingo K9 4 Operation Maintenance Manual 43 Yanmar Engine Assembly Series I ...

Page 49: ...Dingo K9 4 Operation Maintenance Manual 49 K9 4 Perkins Engine Diagram And Part List ...