8

©

Dinel, s.r.o. CLM–36

BASIC INFORMATION

Level meters with coated electrode have protection cover at the end of electrode, which is necessary

take down before mounting.

Level meters mount in vertical position to upper lid of tank or reservoir by steel welding

flange ON-36x2 (steel 11375), stainless steel welding flange NN-36x2 (stainless steel 1.4301),

fixing nut UM-36x2 (stainless steel 1.4301) or Clamp flange.

For mounting level meter to the metal tank or reservoir is not necessary to ground housing

again.

In case of installation in concrete sumps or silos it is properly to install level meter at metallic

auxiliary construction (console, lid, etc.) and then connect with metal all the time submerged object,

eventually with steel armouring.

For measuring of material in plastic and glass vessels by level meter without reference tube

is necessary to connect grounding screw at housing with auxiliary electrode which is fixed by the

appropriate method to the outer casing of vessels (or at inner wall). Material of auxiliary

electrode

is necessary to choose with consideration to the working environment and properties of measured

material.

Please follow next 4 steps:

• i

nstallation

• e

lectrical

connection

• p

reparing

of

level

Meter

for

Measuring

6 . i

nstallation

and

putting

into

operation

7 . i

nstallation

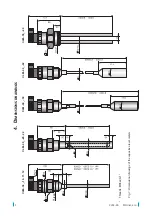

CLM-36_-10, 11, 12

METAL AND NON-METAL VESSESLS

E

- the length of electrode

[mm] - the end of the electrode

has to be dipped min. 20 mm

below the lowest measured level

h

- the distance from the

bottom - min. 50 mm

a

- the distance from the wall -

min. approx. E/20

d

- the diameter of auxiliary

tube vessel - min. 40 + E/20

(smaller dimension has to be

discussed with producer)

auxiliary electrode

width = min. 30 mm

(necessary only for

non-metal vessels)

Fig. 4: Installation of level meter with rod electrode

• s

etting

Summary of Contents for CLM-36

Page 2: ......

Page 27: ...26 Dinel s r o CLM 36...