Digitronic

Digital Cam Switch Unit

Automationsanlagen GmbH

CamCon DC16

9. Error messages and removal of errors (FAQ)

The error messages appear on the standard display or in CamCon DC16, 90, 115, 300 and 1756-

DICAM without a display of their own through the status LED or status bits. See Chapter 4.7. The

status LED on page 24.

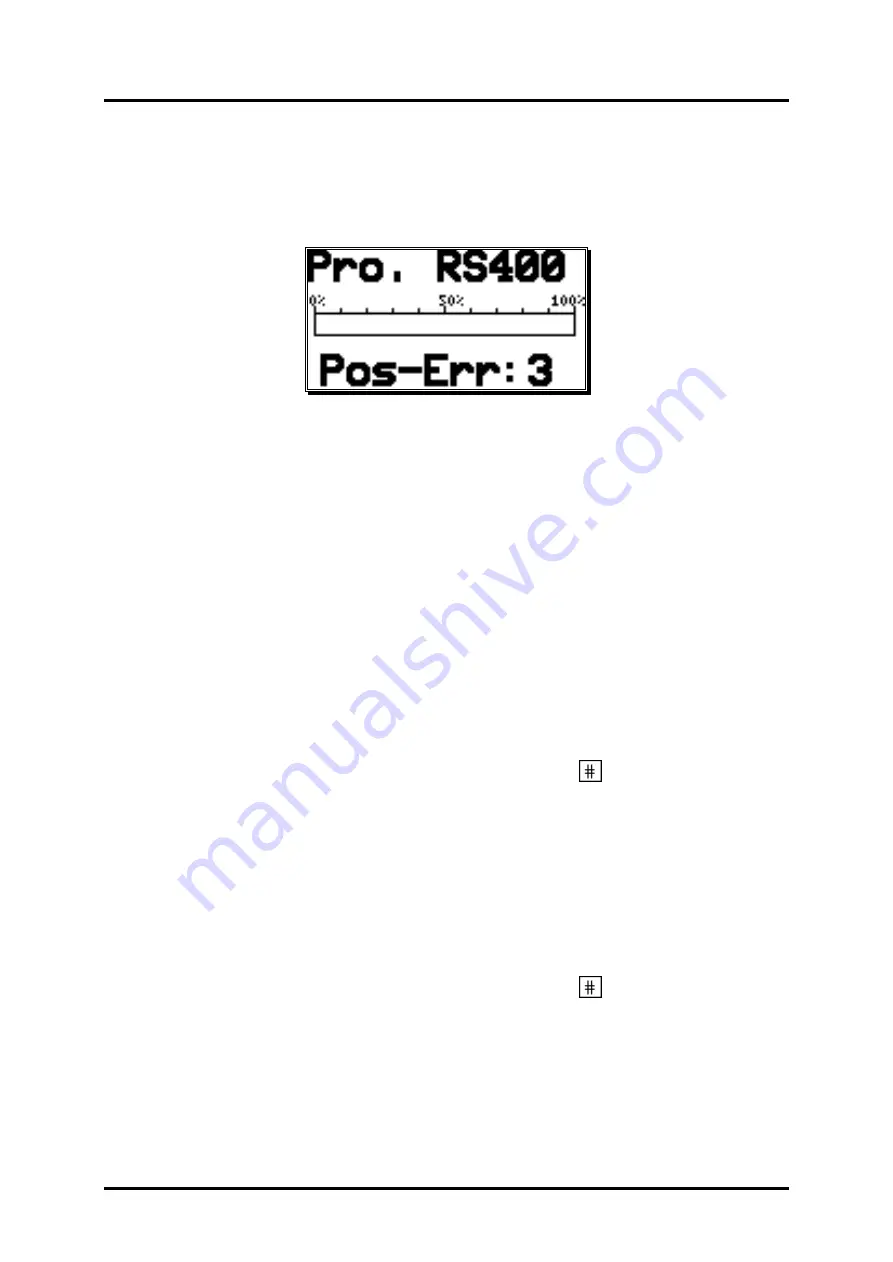

The drawing below shows the error message appearing for 'Position - Error 3'.

The display for other errors is almost the same.

9.1 Problem: Display shows "No contact to unit: XX".

Possible causes:

The wiring is probably not correct, no device with the selected unit number is on the BUS or the setting

of the 'Ser.Mode' is wrong.

Solution:

Check the wiring and the configuration of the serial interface.

See chapter "4.1.7. Pin allocation of the serial RS485 interface" on page 16 and chapter "7.5.3. Unit

configuration" on page 68.

9.2. Problem: "Pos - Err:1".

Possible causes:

The measuring system has not been correctly connected.

Solution:

Please check the wiring to the measuring system. Please consult the instruction manual to the

measuring system.

If the error is eliminated, the error-message can be deleted by pressing

9.3. Problem: "Pos - Err:2".

Possible causes:

The measuring system is faulty or not connected.

The setting of the error bits in the special measuring system setting is not correct.

Solution:

Check the wiring to the measuring system.

Check the inputs of the measuring system resolution.

Consult the instruction manual of your measuring system.

If the error is eliminated, the error-message can be deleted by pressing

Version: Aug. 04

Page: 78