21

DHOLLANDIA

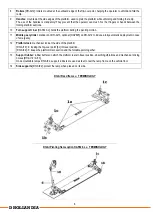

Position the ramp as far as possible towards the outside,

but keep a gap of min. 25 mm between the ramp and the

closed doors.

Verify if the platform can be deployed in its work position

without interfering with the rear sill of the vehicle floor, the

bumper or other possible obstructions. Use the provided

bumper clearance dimensions in section 7.4 on page 14.

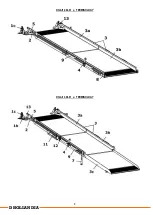

If technically possible, it is recommended to mount the ramp in the center of the vehicle, but it can be installed in asymmetric

position as well. E.g. in function of the bolt positions and possibilities to mount flanges and nuts at the underside of the vehicle

floor, or simply on client’s request.

After determining the ramp position and before drilling any holes, make sure there is sufficient space at the underside of the

vehicle floor to mount flanges (to spread the forces of the bolts over a wider area) and the nuts of the mounting bolts.

* =

* =

EXAMPLE

Summary of Contents for DH-AI02.04.01

Page 10: ...9 DHOLLANDIA DH AI12 04 01 TERMINOLOGY DH AI13 04 01 TERMINOLOGY...

Page 11: ...10 DHOLLANDIA DH AI12 10 01 TERMINOLOGY Portable ramp DH AI02 04 01 TERMINOLOGY...

Page 15: ...14 DHOLLANDIA 7 4 TECHNICAL SPECIFICATIONS DH AI12 04 01...

Page 16: ...15 DHOLLANDIA DH AI12 10 01...

Page 17: ...16 DHOLLANDIA DH AI13 04 01...

Page 18: ...17 DHOLLANDIA DH AI02 04 01...