D

e

WALT

replacement parts are recommended. Do not use

modified parts or parts that will not give performance equal

to the original equipment.

CAUTION

: Be sure to remove the battery and fuel cell during

clearing jams, inspection, maintenance and cleaning.

JAM CLEARANCE

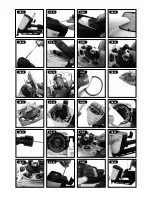

If nails are jammed in firing head, remove it, and adjust the

nailing in the following order.

1. Remove the fuel cell and the battery from the Nailer.

2. Pull the pusher back in magazine and remove fasteners.

3. Remove the bolts with wrench (Fig. 17 & 18).

4. Pull magazine away from the firing head, and clear jam

(Fig. 19 & 20).

5. Connect the fuel cell and the battery to the Nailer.

INSPECTING THE MAGAZINE

1.

First, remove the fuel cell and the battery from the nailer.

2.

Clean the magazine. Remove paper chips or wooden

chips which may have accumulated in the magazine.

Lubricate it with

D

e

WALT

gas finish nailer lubricant.

CHECKING MOUNTING SCREWS

At regular intervals, check every part for loose mounting

screws and tighten any loose screws found. Operating the

tool with loose screws will can be hazardous.

INSPECTING THE CONTACT ARM

Check if the contact arm can slide smoothly.

Clean the sliding area of the contact arm and use

the provided oil for lubrication from time to time.

This will enable a smooth operation and simultaneously help

to prevent the formation of rust.

PREPARATION FOR STORAGE

l

When not in use for an extended period, apply a thin

coat of the lubricant to the steel parts to avoid rust.

l

Do not store the nailer in a cold weather environment.

When not in use, the tool should be stored in a warm

and dry place.

l

Keep out of reach of children.

l

Refer to all instructions in the previous ‘Storage’

section of this manual.

SERVICE PARTS LIST

CAUTION

: Repair, modification and inspection of

D

e

WALT

Power Tools must be carried out by a

D

e

WALT

Authorised

Service Center.

The Parts List supplied with this tool will be helpful if

presented with the tool to the

D

e

WALT

Authorised Service

Center when requesting repair or other maintenance.

In the operation and maintenance of power tools, the safety

regulations and standards prescribed in each country must

be observed.

MODIFICATIONS

D

e

WALT

tools are constantly being improved and modified

to incorporate the latest technological advancements.

Accordingly, some parts may be changed without prior

notice.

APPLICABLE LUBRICANTS

Use

D

e

WALT

Gas Nailer lubricant.

Do not use detergent oil or additives: these lubricants will

harm the O-rings and other rubber parts and will cause the

tool to malfunction.

NOISE AND VIBRATION DATA

NOISE EMISSION (See Tool Technical Data)

The characteristic noise values for the tool have been

determined in accordance with EN 12549 - “Acoustics

- Noise test code for fastener driving tools - Engineering

Method.”

These values are tool related characteristic values and do

not represent the noise development at the point of use.

Noise development at the point of use will depend for

example on the working environment, the work piece, the

work piece support and the number of driving operations,

etc.

Depending on the conditions at the workplace and the form

of the work piece, individual noise attenuation measures

may need to be carried out, such as placing work pieces on

sound damping supports, preventing work piece vibration by

means of clamping or covering, adjusting to the minimum

air pressure required for the job, etc.

INFORMATION ON VIBRATION (see Tool Technical Data)

The characteristic vibration value for the tool has

been determined in accordance with ISO/WD 8662-11

“Measurement of vibration in hand held power tools - Part

11 Fastener Driving Tools”.

ENGLISH

15

Summary of Contents for DGN9033-XJ

Page 2: ...DGN9033 XJ ...

Page 4: ...3 ...