Appendix - I/O and events_02/2017

- 20 -

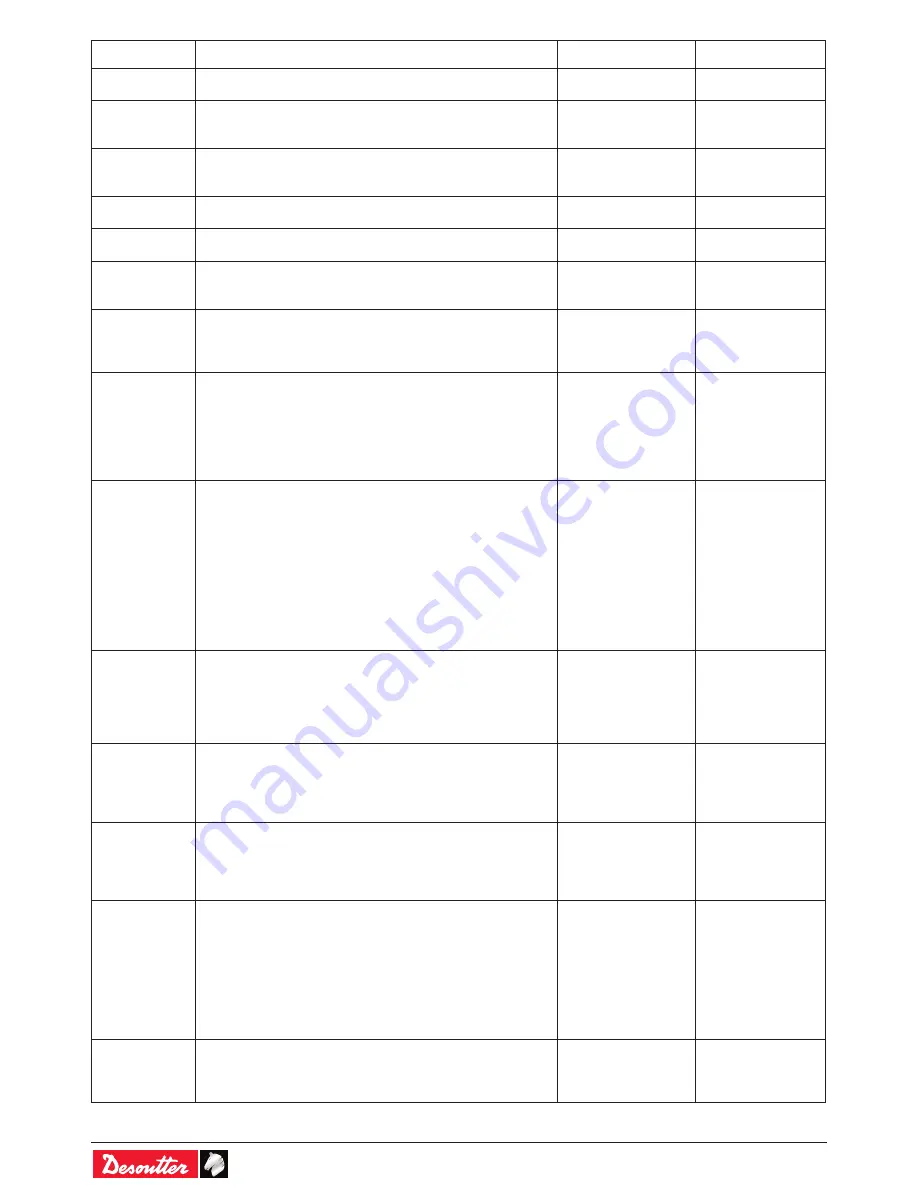

Name

Description

Raising condition

Falling condition

Tool main start

trigger

Reflects the raw state of tool main course start trigger,

independently from the Tightening Unit state.

Trigger is pushed.

Trigger is released

Tool push start

or front start

trigger

Reflects the raw state of tool push start or front start trigger,

independently from the Tightening Unit state.

Trigger is pushed.

Trigger is released

Manual reverse

in progress

The operator has selected the reverse direction on the tool and

is running the tool.

Manual runreverse

selected and trigger

pushed.

Stays on as long

as the operator is

running the tool

Fastener

loosened

There is a fixed minimum torque value to declare that the

fastener was "loosened".

Run reverse

Result generation.

New start (tool trigger

or external start)

Tube nut open

Indicates that the tube nut is open.

The tool can be removed from the assembly.

-

Tool running

Tool

maintenance

alarm

Reflects the different tool maintenance alarm state with or

condition.

Tool maintenance

alarm 1 or 2 is active.

No tool maintenance

alarm is active.

Invalid spindle

settings

Tool characteristics does not match Pset parameters (e.g.

negative jog times or contradictions, torque over the maximum

tool torque range, speed over the maximum tool speed,

maximum tool torque range, etc…)

Pset selection or tool

connection.

Tool disconnection or

new Pset selected.

Span failure

When starting a tightening, before running the tool, the

controller checks the torque span.

"Span failure" indicates that the span drifts by ±3% or more,

causing a tool lockout.

This fault can be due to the torque transducer or the tool

electronics.

The only solution is to replace the tool.

Span failure detection. Disconnecting tool

or new check without

fault.

Offset failure

Indicates the offset (0 point) drifts by 50 % of full scale or

more.

This error exists when, at the beginning of the Pset, the torque

transducer is seen to have 50 % or more of full-scale torque

prior to even starting the motor. With an "Offset failure", the

controller cannot adequately compensate for this transducer

error and, therefore, will not allow a tightening operation to

occur.

The only solution is to replace the tool.

Offset failures can come from a severely damaged torque

transducer, a bad field cable or a bad controller.

Offset failure detection Disconnecting tool

or new check without

fault.

Motor over

temperature

Indicates that the temperature of the tool motor windings has

exceeded the temperature threshold.

An error message remains.

Temperature

threshold:

- 100°C for fixed tools

- 60°C for portable

tools

The signal turns

off as soon as the

temperature returns

below the threshold

(minus hysteresis =

10°C).

Angle

measurement

fault

Drive detected angle sensor fault.

It can be an angle sensor fault, a tool electronic fault or a

combination of both.

The communication is tested permanently.

As soon as the fault disappears, the signal turns off.

Angle fault detection.

Disconnecting tool

Angle

measurement

fault

Drive detected angle sensor fault.

It can be an angle sensor fault, a tool electronic fault or a

combination of both.

The communication is tested permanently.

As soon as the fault disappears, the signal turns off.

Angle fault detection.

Disconnecting tool

No tool

connected

Indicates that the controller is not detecting the tool.

Controllers are designed to work with a range of fastening

tools. The tools have an Intelligent Tool Interface (ITI) board

which is continuously sending status information to the

controller. If the controller requests status information from the

tool and gets no response, the controller software turns on the

"No tool connected" output.

This output resets immediately upon successful

communication with a tool.

No tool connected or

tool not recognized

Tool connected and

recognized.

Redundancy

error

Redundancy error in case of operational control transducer

and faulty monitoring transducer.

Result generation

Use of "reset of

redundancy error"

input, change of tool

free of this error

Summary of Contents for CVI3 Function

Page 2: ......

Page 5: ...Table of contents_02 2017 5...

Page 27: ...Appendix I O and events_02 2017 27...

Page 35: ...Appendix User info codes_02 2017 35...

Page 43: ......

Page 44: ...www desouttertools com Copyright 2017 More Than Productivity...