Clock Box PRO Installation and Operations Manual V1.1

LAB-110218

11

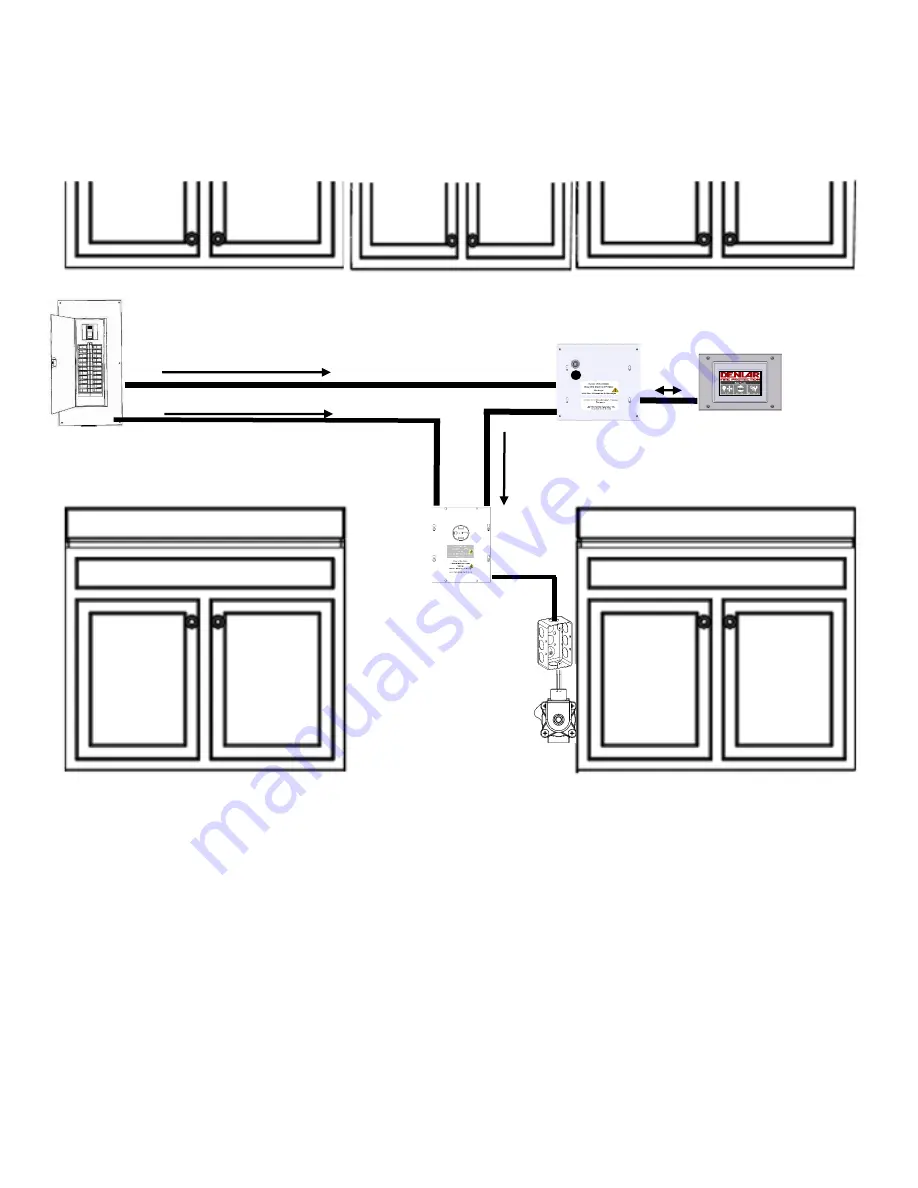

Clock Box PRO Stand-Alone Interface Diagram

Non-

Plug‘N’Play

1.

Cable providing 120 VAC from Main Breaker Panel to the Clock Box PRO (not provided)

a.

Connect the Line side to position four of the eight (8) position connector in the Clock Box PRO

Control Box Power Plug

b.

Connect the Neutral side to position two of the eight (8) position connector in the Clock Box PRO

Control Box Power Plug

c.

Connect the Ground side to position three of the eight (8) position connector in the Clock Box PRO

Control Box Power Plug

2.

24 VDC Input / Output Communication cable encased in 16 mm ENT Flexible Conduit (provided)

a.

25 Ft in length

b.

One communication (Ethernet) cable and one plenum cable

c.

Connects to the Clock Box PLC and HMI / Touch Screen

3.

120 VAC Output from the Clock Box PRO encased in 16 mm ENT Flexible Conduit (provided)

Electrical Disconnect

120 VAC Input (not provided)

2

5

3

CB1 / CB2

4

1

Summary of Contents for ClockBox Pro

Page 1: ...Clock Box PRO Installation and Operations Manual V1 1...

Page 10: ...Clock Box PRO Installation and Operations Manual V1 1 LAB 110218 10 Device Flow Chart...

Page 27: ...Clock Box PRO Installation and Operations Manual V1 1 LAB 110218 27...

Page 34: ...Clock Box PRO Installation and Operations Manual V1 1 LAB 110218 34 Clock Box PRO Schematic...

Page 35: ...Clock Box PRO Installation and Operations Manual V1 1 LAB 110218 35 Clock Box PRO Datasheet...

Page 36: ...Clock Box PRO Installation and Operations Manual V1 1 LAB 110218 36 Gas Disconnect Datasheet...