5.4

Installation procedure

1.

Unpack and dispose of the packing material in an environmentally compatible way

2.

Check the delivery is complete

"Transport, packing and storage", Page 17.

3.

Release air from the friction wheel travel drive

"Preparing for installation", Page 25.

4.

Assemble the DRF 200 with trolley.

5.

Attach the hoist unit.

6.

Connect to the power supply

"Connecting the electric equipment", Page 31.

7.

Carry out checks before putting the unit into operation for the first time

"Putting into service for the first

8.

The equipment is ready for operation

5.5

Preparing for installation

Releasing air from the friction wheel travel drive

Replace the plug screw at the highest point of the friction wheel travel drive with the vent screw included in the

supply. If this is not done, the friction wheel travel drive may leak due to the overpressure that is created.

Adjusting the dished washer stack

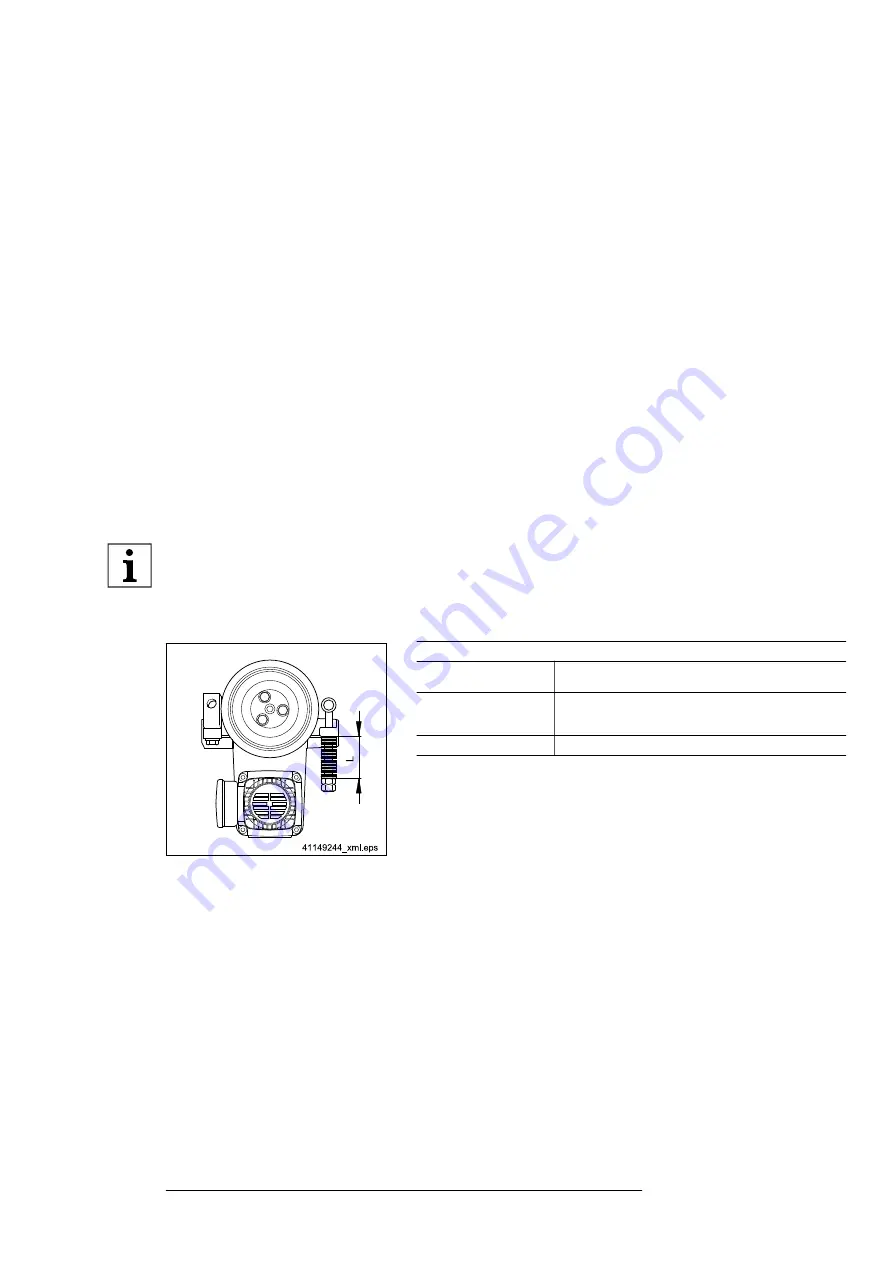

Fig. 11

Friction wheel with HydroPUR tyre

Contact pressure F

P

max.

[N]

3900

Dished washers

Stack consisting of 38 dished washers, single washers ar‐

ranged alternately L = 91,2 mm.

Order no. 339 757 99 (31,5 x 16,3 x 1,5)

Adjustment length

L [mm]

76

Tab. 17

3)

HydroPUR is a low-wearing hydrolysis-resistant polyurethane.

4)

Adjustment length applies to the specified spring length L

O

. Modify accordingly to correct for different dimensions.

214

39

5 44/120

914

25

Summary of Contents for DRF 200

Page 51: ...214 395 44 120914 51...