Introduction

Installation Manual

5

Introduction

Overview

Delta’s 100kW Power Conditioning System (PCS) is a bi-directional conversion system that converts

power between energy storage and grid, along with energy and grid power quality management

features.

It supports demand charge management by peak shaving, enables load shifting for time-of-use

savings, and provides real power and reactive power compensation to improve power quality.

With Delta’s PCS solution you can realize the fullest value of an energy storage system.

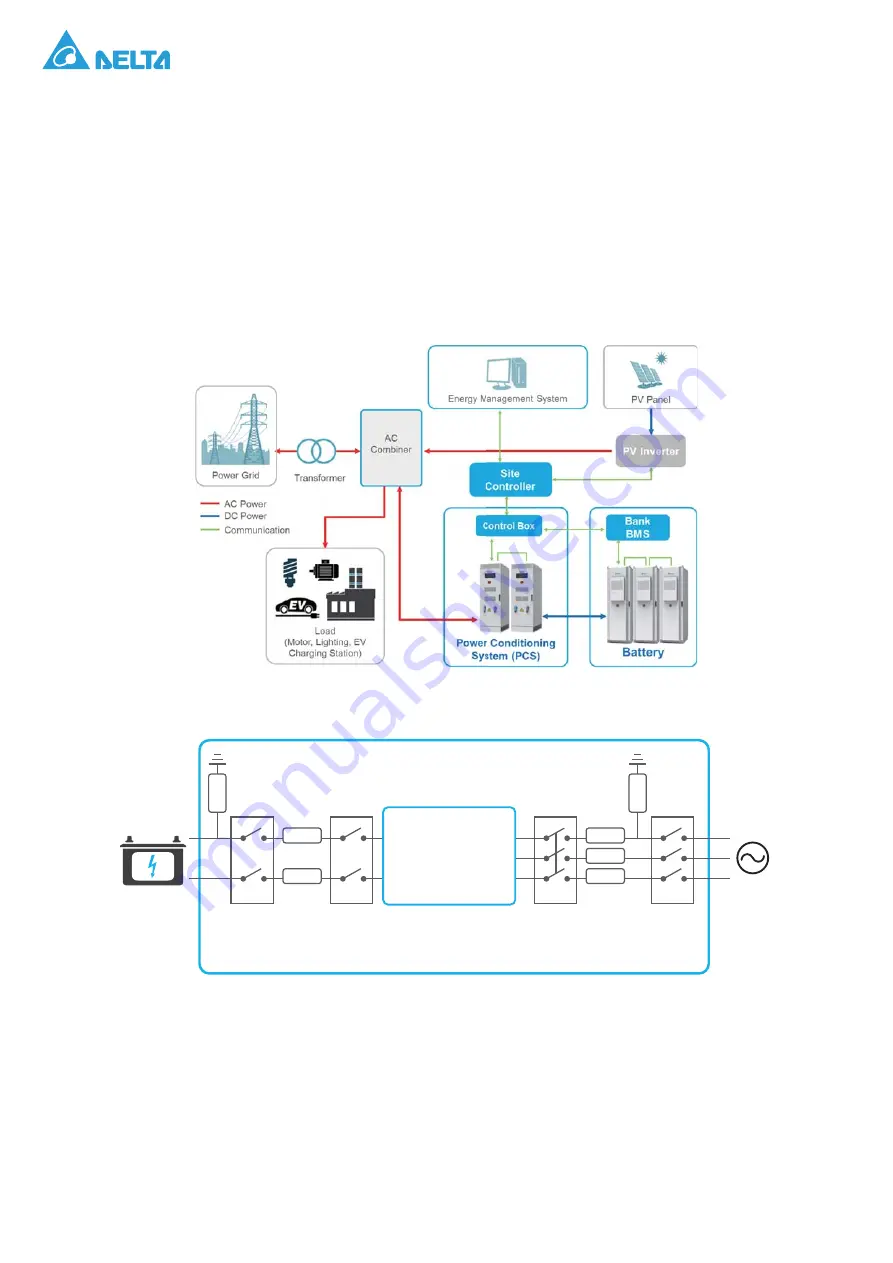

Figure 1.

Typical PCS Application System Architecture

Figure 2.

Delta 100kW PCS System Block Diagram

750-1000 Vdc

DC

Switch

DC

Fuse

AC

Fuse

400 Vac

3P-3W

L1

L2

L3

AC

Contactor

DC

Relay

SPD

SPD

100kW Bi directional

DC/AC Inverter

Module

Grid

100kW PCS Cabinet

Battery