36

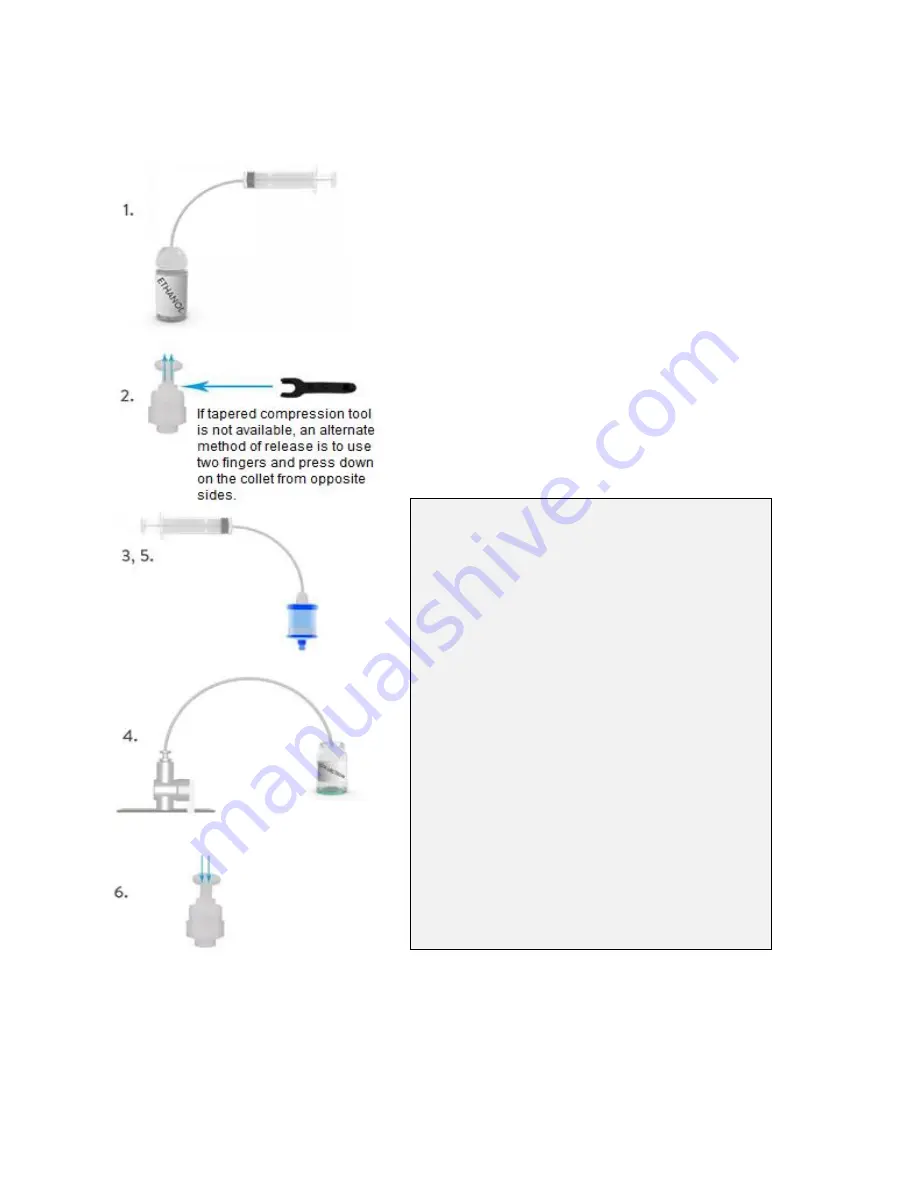

Oiler Flush Procedure

This procedure should be performed every 2-4

weeks, or if the liquid in the oiler is no longer clear.

The procedure flushes the internal mechanics and

cleans the system of debris.

The liquid in the oiler may not change color at all

–

It may change due to extensive heat or

temperature variances. The oiler flushing

procedure keeps the system clean for continued

use, whether or not the liquid in the oiler changes

color.

1) Fill Syringe with 200 proof Ethanol.

2) Use tapered compression tool to compress

lower half of plastic coupling, while pulling the

stem plug out of the coupling.

3) Insert nylon tubing into plastic coupling.

Attach other end of tubing to syringe filled with

Ethanol.

4) Open flush valve, insert second plastic tube

into fitting. Feed the other end of the tubing

into a jar or other collection vessel.

5) Apply force to the syringe plunger, which

should cause ethanol to flow from syringe into

oiler assembly

– ethanol should immediately

begin to flow out of the flush tube and into the

collection vessel. Flush until ethanol coming

out is clean, clear, and free of any settlement.

6) Close flush valve and reinstall plastic

coupling stem into oiler assembly.