Delem

V0505, 2.7

2.4.

Large Radius: Bumping

To make a bend with a large radius, the control uses the bumping method. With this method, a

large radius in a product is obtained by a series of slight bends in succession.

2.g

To program such a bend, you must program the following parameters:

radius = the desired radius

segments = number of segments

The number of bends in this radius is the number of segments plus 1.

The more segments you select, the more bendings will be used to create the programmed

radius within a smaller tolerance. With a high number of segments you will need a smaller V-

die opening to be able to bend in a proper way. Which value is acceptable as maximum for the

V-opening of the die is calculated and displayed on the screen.

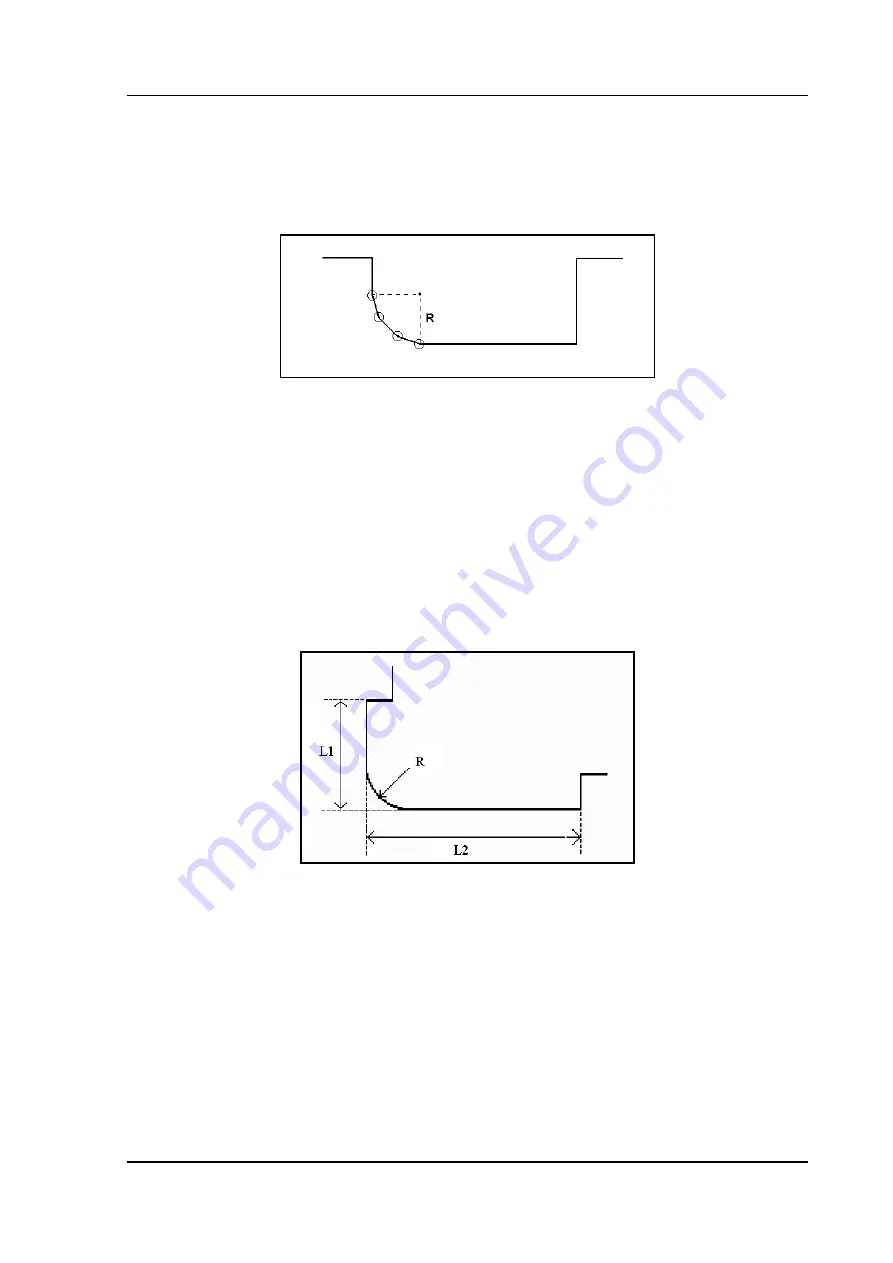

For the definition of the line lengths to be programmed in the part connected to a bump radius

segment, see figure 2.h.

2.h

Lengths L1 and L2 must be equal or bigger than the radius R.

When you must program such a bend, first program a standard angle with adjacent sides. Then

put the cursor back on the angle and press the function key ‘bumping’ (S2). You will be

prompted to program the radius and the number of segments. After programming these param-

eters the radius is drawn in the product and the maximal V-opening which can be used is dis-

played on the screen. This is shown in figure 2.i.