DT1012 IP

32

20221107-V0

9. Dismounting

9.1. Dismounting procedure

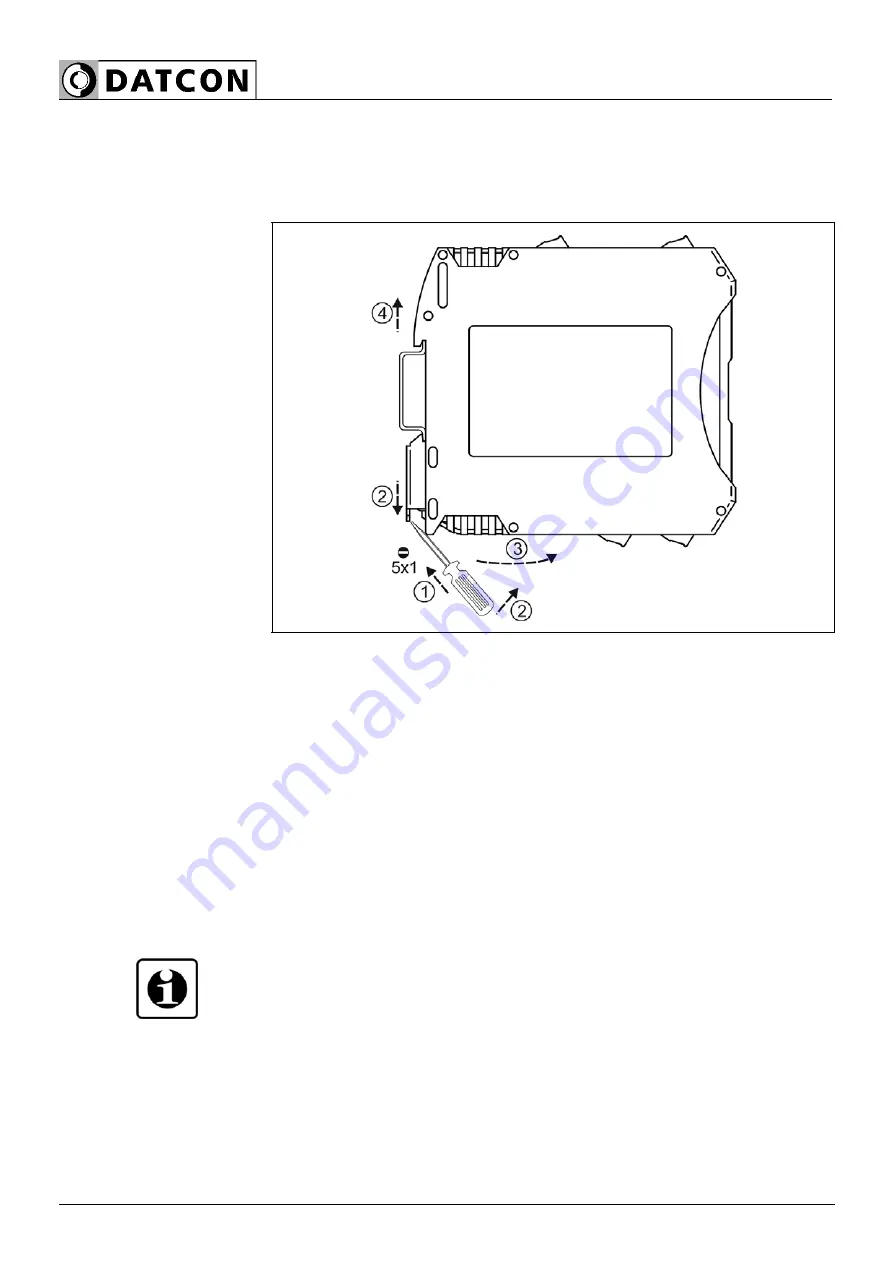

The following figure shows the dismounting procedures:

Dismounting from the

rail

The dismounting procedure needs a screwdriver for slotted screws.

1. Switch off the power supply

2. Disconnect all wires.

3. Put the screwdriver end into the fixing assembly’s hole (figure

step 1.).

4. Lift the screwdriver handle until it possible to open the fixing

assembly (figure step 2.).

5. Keeping the screwdriver in this position lift the instrument bottom

from the bottom edge of the rail (figure step 3.).

6. Lift the whole instrument (you may put out the screwdriver) (figure

step 4), the instrument will be free.

9.2. Disposal

According with the concerning EU directive, the manufacturer

undertakes the disposal of the instrument that are manufactured by it

and intended to be destroyed. Please deliver it in contamination-free

condition to the site of the Manufacturer or to a specialized recycling

company.

stop