CR825 and CE875 Instant Issuance System Installation and Administrator’s Guide

A-1

Appendix A: CE875 Instant

Issuance System

This appendix provides information about setting up the CE875 instant

issuance system.

Introduction

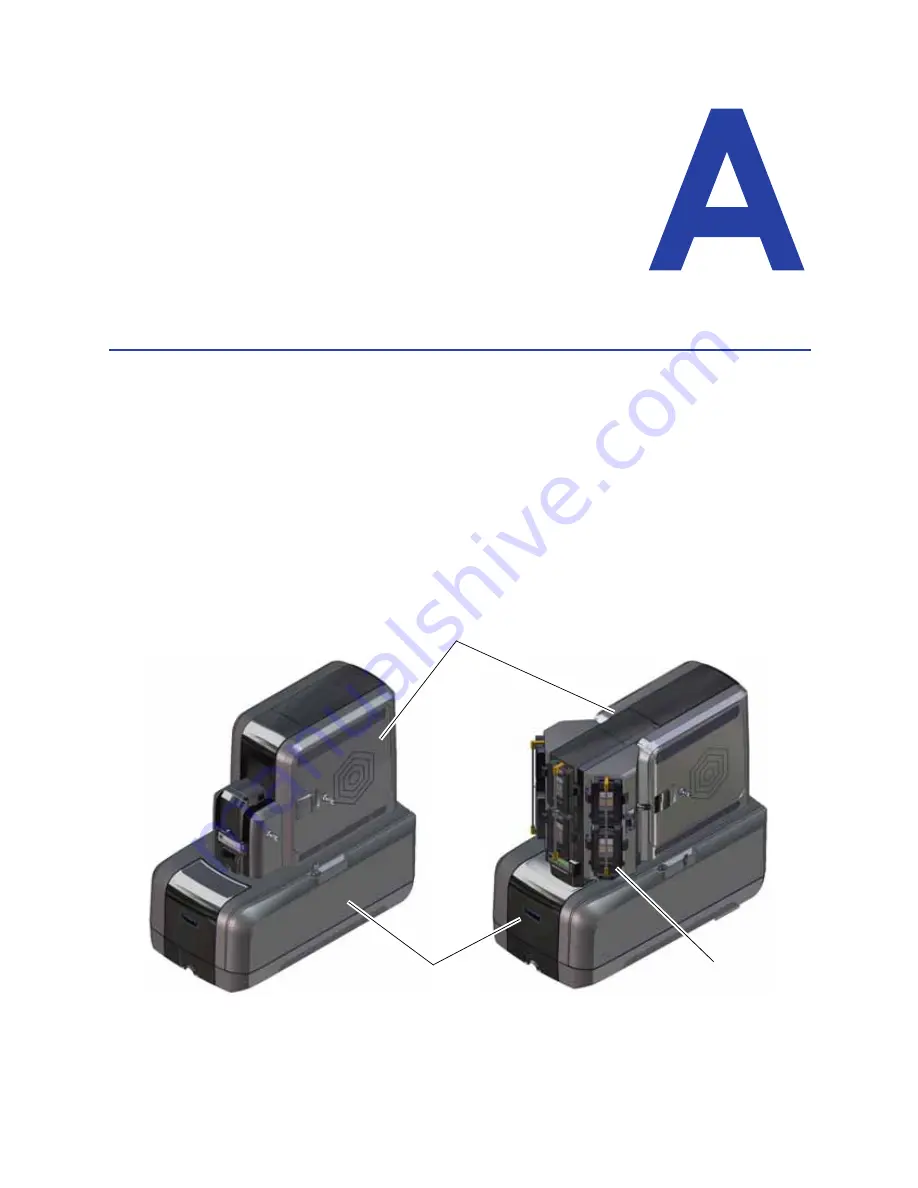

The CE875 system consists of a card printer and the CEM embosser. The CE875 system can print

cards and then emboss and indent characters on the card. The embosser creates the raised

lettering and numbering on the front and back of most financial or debit cards.

The embosser can contain an embossing wheel and topping and indent ribbon cartridges. The

embossing wheel can have up to 75 punch and die (emboss) or punch and anvil (indent) pairs. A

second wheel option allows for up to 75 additional emboss characters. Multiple font choices and

a variety of special characters are available for the embossing wheel.

Printer

Embosser

Multi-Hopper

Single-Hopper System

Multi-Hopper System

Summary of Contents for CR825

Page 8: ...viii...

Page 10: ...x...

Page 16: ...xvi...

Page 20: ...4 Printer Installation Multi Hopper Printer 13 4 in 340 mm 16 2 in 411 mm 25 6 in 651 mm...

Page 28: ...12 Printer Installation Unpack the Optional Multi Hopper...

Page 54: ...38 Printer Installation...

Page 70: ...54 Elements of Card Design...

Page 112: ...96 Printer Manager...

Page 129: ...CR825 and CE875 Instant Issuance System Installation and Administrator s Guide A 9...

Page 140: ...A 20 CE875 Instant Issuance System...