9

MG.10.P2.22 - VLT is a registered Danfoss trademark

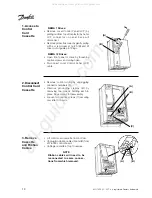

Installation

The following section describes the

installation procedures for the Modbus RTU

option card. For additional information on

installation and operation of the VLT 6000,

refer to the

VLT

6000 Operating Instructions

.

VLT adjustable frequency drive

contains dangerous voltages

when connected to line voltage.

After disconnecting from power

line, wait at least 14 minutes

before touching any electrical

components.

Only a competent electrician

should carr y out electrical

installation. Improper installation

of motor or drive can cause

equipment failure, serious injury

or death. Follow this manual,

National Electrical Codes and

local safety codes.

CAUTION

!

CAUTION

!

Electronic components of

adjustable frequency drive and

Modbus RTU option card are

sensitive to electrostatic

discharge (ESD). ESD can reduce

performance or destroy sensitive

electronic components. Follow

proper ESD procedures during

installation or servicing to prevent

damage.

It is responsibility of user or

installer of VLT adjustable

frequency drive to provide

proper grounding and motor

overload and branch protection

according to National Electrical

Codes and local codes.

Modbus RTU

Option Card

Environmental

Requirements

Environmental requirements for the Modbus

RTU option card are listed below.

Description

Requirement

Operating temperature

-5

°

F to +140

°

F (-20

°

C to +60

°

C)

Storage temperature

-40

°

F to +176

°

F (-40

°

C to + 80

°

C)

Humidity

5% to 95% relative, non-condensing

DANGER

!

WARNING

!

Power

Supply

The Modbus RTU option card is powered by

24 VDC and draws 38 mA of current at 24V.

All manuals and user guides at all-guides.com