Installation

System pressure test

Pressurize the system on HP side first then LP

side to prevent rotation of the scroll. Never let

the pressure on LP side exceed the pressure on

HP side with more than 72 psi.

On SY/SZ240-300 models which have an

internal non return-valve in discharge fitting

or if an external non return valve is present on

the discharge line, we advise to pressurize the

system not quicker than 70 psi/s to allow enough

pressure equalisation between LP and HP side

over the scroll elements.

Always use an inert gas such as nitrogen for

pressure testing. Never use other gasses such as

oxygen, dry air or acetylene as these may form

an inflammable mixture. Do not exceed the

following pressures:

Moisture obstructs the proper functioning of the

compressor and the refrigeration system.

Air and moisture reduce service life and increase

condensing pressure, and cause excessively high

discharge temperatures, which can destroy the

lubricating properties of the oil. Air and moisture

also increase the risk of acid formation, giving

rise to copper platting. All these phenomena

can cause mechanical and electrical compressor

failure.

For these reasons it’s important to perform a

vacuum dehydration on the system to remove

all residual moisture from the pipe-work after

assembly;

SM / SY / SZ compressors are delivered with

< 100 ppm moisture level. The required moisture

level in the circuit after vacuum dehydration

must be < 100 ppm for systems with an SM / SY

/ SZ.

• Never use the compressor to evacuate the

system.

• Connect a vacuum pump to both the LP & HP

sides.

• Evacuate the system to a pressure of 0.02 inHg

(300 μm Hg) absolute.

Do not use a megohm meter nor apply power to

the compressor while it’s under vacuum as this

may cause internal damage.

Vacuum evacuation and

moisture removal

Leak detection must be carried out using a

mixture of nitrogen and refrigerant or nitrogen

and helium, as indicated in the table below.

Never use other gasses such as oxygen, dry air

or acetylene as these may form an inflammable

mixture.

Pressurize the system on HP side first then Low

side.

Leak detection

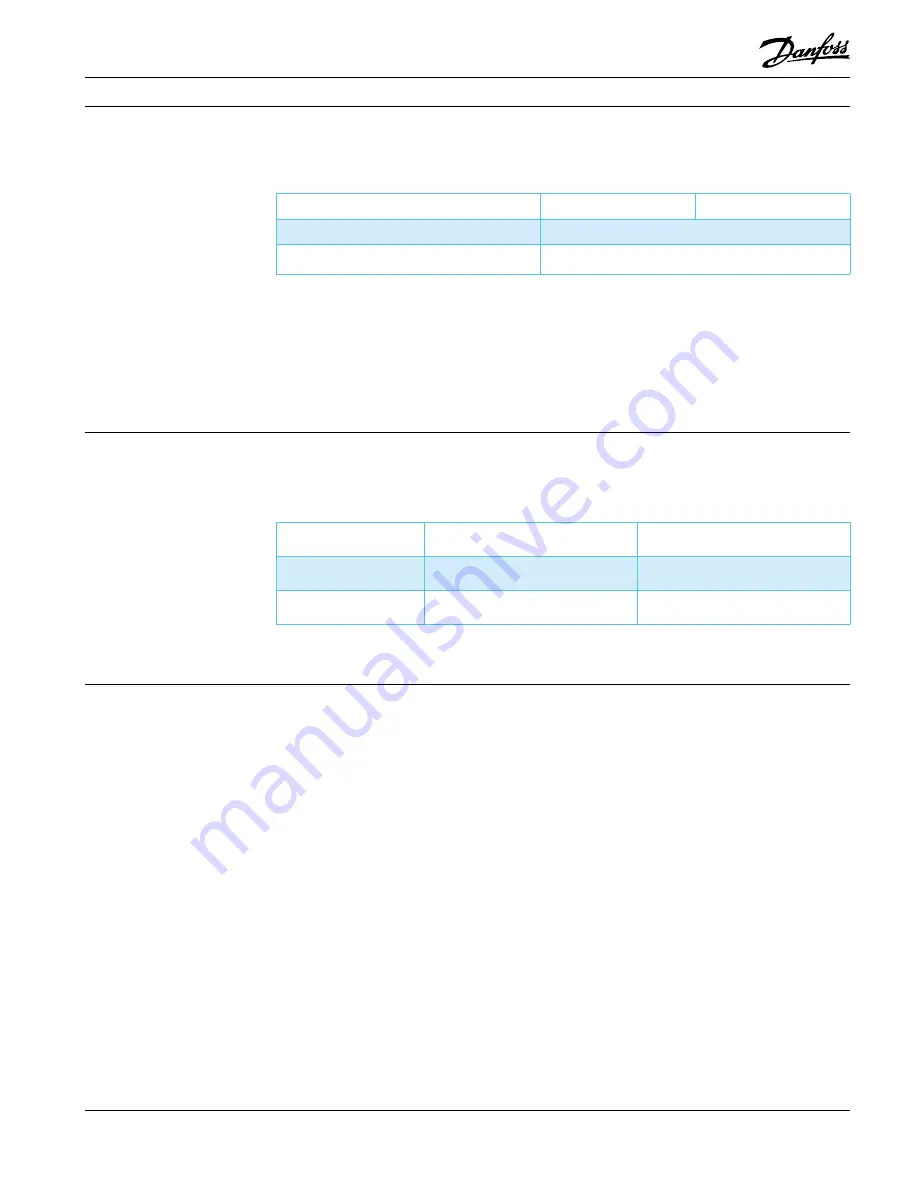

Maximum compressor test pressure (low side)

SM/SZ 084 - 185: 363 psig

SZ/SY240 - 380: 290 psig

Maximum compressor test pressure (high side)

464 psig

Maximum pressure difference between high and

low side of the compressor:

348 psig

Compressor model

Leak detection with refrigerant

Leak detection with a mass spectrometer

SM-SY compressors

Nitrogen & R22

Nitrogen & Helium

SZ compressors

Nitrogen & R134a or R407C

Nitrogen & Helium

Note 1:

Leak detection with refrigerant may be forbidden in some countries. Check local regulations.

Note 2:

The use of leak detecting additives is not recommended as they may affect the lubricant properties.

45

FRCC.PC.003.A5.22

Application guidelines